AISI 1055 Steel/S55C Steel

Product Name:

AISI 1055 Steel/S55C

Material:

AISI 1055 Steel/S55C

Category:

medium carbon steel

Processing available:

Kaiping, slitting, cold rolling, quenching, and tempering

Breif Introduction:

Huaxia-steel is a professional carbon steel suppliers of AISI 1055 Steel with more than ten years of export experiences and timely response within 12 hours. Welcome to send us inquiries directly.

Contents

Product Introduction

As one of the leading carbon steel suppliers in China, Huaxia-Steel is proud to offer AISI 1055 Steel/S55C Steel to our customers worldwide. AISI 1055 Steel/S55C Steel is a medium carbon steel that is widely used in various industries due to its high strength and excellent impact resistance. It is ideal for applications where high strength and toughness are required, such as gears, shafts, and axles.

At Huaxia-Steel, we are committed to providing our customers with high-quality products and exceptional service. We source our AISI 1055 Steel/S55C Steel from top-rated mills in China, ensuring that our customers receive only the best quality products. We also offer a range of processing services to meet our customers’ specific requirements, including cutting, drilling, and machining.

As a trusted carbon steel supplier, we take pride in our ability to deliver products that meet or exceed our customers’ expectations. Whether you are in need of AISI 1055 Steel/S55C Steel for your next project or any other type of carbon steel, Huaxia-Steel is your one-stop-shop for all your steel needs.

AISI 1055 Steel/S55C Steel is a medium carbon steel with good toughness, strength, and wear resistance. It is widely used in various industries, including automotive, machinery, and construction. The main features of AISI 1055 Steel/S55C Steel are:

High strength: AISI 1055 Steel/S55C Steel has good tensile and yield strength, making it suitable for applications where strength is critical.

Good toughness: The steel has excellent toughness, which means it can withstand heavy impact and loading without breaking.

Wear resistance: AISI 1055 Steel/S55C Steel has good wear resistance, making it suitable for parts that undergo friction and wear.

As carbon steel suppliers, we take pride in providing high-quality AISI 1055 Steel/S55C Steel to our customers. Our steel is manufactured using advanced techniques and state-of-the-art technology to ensure that it meets international standards. With our expertise and experience, we can supply AISI 1055 Steel/S55C Steel in various shapes and sizes to meet your specific needs. Contact us today to learn more about our products and services.

AISI 1055 Steel/S55C Steel is a popular choice for many industries due to its numerous advantages. One of the primary benefits is its high carbon content, which gives it exceptional hardness and strength. This makes it ideal for manufacturing heavy-duty machine parts, tools, and equipment that require high durability and wear resistance.

Another advantage of AISI 1055 Steel/S55C Steel is its excellent machinability, which allows for easy shaping and fabrication. It can be easily welded, cut, and drilled, making it a versatile choice for many applications. Additionally, it has good ductility and toughness, making it resistant to deformation and cracking under stress.

Furthermore, AISI 1055 Steel/S55C Steel is cost-effective and readily available from carbon steel suppliers, making it an attractive option for many businesses. Its properties also make it suitable for a wide range of applications, including construction, automotive, manufacturing, and more.

In summary, AISI 1055 Steel/S55C Steel offers outstanding strength, durability, machinability, and affordability, making it an excellent choice for various applications. As one of the leading carbon steel suppliers in China, Huaxia-Steel offers high-quality AISI 1055 Steel/S55C Steel products that meet international standards and specifications.

AISI 1055 Steel/S55C Steel Applications

AISI 1055 Steel/S55C Steel is a high-quality carbon steel grade with excellent mechanical properties, making it suitable for a variety of industrial applications. As one of the leading carbon steel suppliers in China, Huaxia-Steel offers AISI 1055 Steel/S55C Steel in various forms, including bars, tubes, and sheets, to meet the specific needs of our customers.

The versatility of AISI 1055 Steel/S55C Steel makes it suitable for use in various industries such as automotive, construction, and engineering. The high strength and hardness of this steel make it ideal for making tools, machinery parts, and structural components.

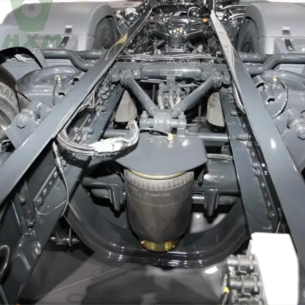

In the automotive industry, AISI 1055 Steel/S55C Steel is used to manufacture crankshafts, gears, and other high-stress components. The construction industry utilizes this steel for manufacturing concrete reinforcing bars, which provide high tensile strength and toughness. Additionally, this steel is often used in the production of industrial machinery, such as press machines, because of its durability and resistance to wear and tear.

As a trusted carbon steel supplier, Huaxia-Steel is committed to providing our customers with high-quality AISI 1055 Steel/S55C Steel that meets industry standards and specifications. We pride ourselves on offering a wide range of products, excellent customer service, and competitive pricing to ensure our customers get the best value for their investment.

AISI 1055 Steel/S55C Material requirements

A572 Grade 50 Steel Plate is a type of high-strength low-alloy steel material that boasts excellent mechanical properties and corrosion resistance. The material requirements for A572 Grade 50 Steel Plate include a maximum carbon content of 0.23%, a maximum manganese content of 1.35%, and a maximum silicon content of 0.4%.

Additionally, the steel must meet specific standards for yield strength, tensile strength, and elongation at break. These requirements ensure that A572 Grade 50 Steel Plate is of high quality and suitable for use in demanding applications where strength, durability, and corrosion resistance are critical. By meeting these material requirements, our company demonstrates its expertise and commitment to providing customers with top-quality products that meet their needs and exceed their expectations.

AISI 1055 Steel/S55C Chemical Requirements

Component | C | Si | Mn | P | S | Cu | Ni | Cr |

Minimum Value | 0.52 | 0.17 | 0.5 | – | – | – | – | – |

Maximum Value | 0.60 | 0.37 | 0.8 | 0.035 | 0.030 | 0.25 | 0.3 | 0.20 |

AISI 1055 Steel/S55C

Mechanical Properties' Requirements

category | yield strength | tensile strength | Elongation | Reduction of area | hardness | Decarburized layer |

Rm | Rm | % | % | Hot Rolled | both sides | |

(Mpa) | (Mpa) | |||||

minimum value | 380 | 645 | 13 | |||

maximum value | 255HB | |||||

Number |

The production for AISI 1055 Steel/S55C Steel

Hot Rolled Stock Specifications

Thickness:

2.0mm~80.0mm

Width:

15mm~620mm, 1,000mm~1,250mm or 2,000mm~2,200mm

Hardness:

No heat treatment ≤ 197HB

Heat Treatment Specification:

Normalized, 820 ℃; Quenching, 820 ℃; Tempering, 600 ℃

Delivery status:

delivery without heat treatment or heat treatment (annealing, normalizing or high-temperature tempering)

Cold Rolled Stock Specifications

Thickness:

0.2mm~6.0mm

Width:

15mm~620mm or 1,000mm~1,250mm

Hardness:

Unheat treated ≤ 255HB

annealed steel, ≤ 217HB

AISI 1055 Steel/S55C Steel is a versatile carbon steel that can be processed in various ways to meet the needs of different applications. As a leading supplier of carbon steel, we offer a range of processing options to our customers.

One of the most common processing methods for AISI 1055 Steel/S55C Steel is hot rolling, which is used to create flat bars, round bars, and other shapes. Cold drawing is another popular processing method, which is used to produce precision tubing and other products with tight tolerances. Forging is also an option for creating custom shapes and sizes.

In addition to these standard processing methods, we also offer value-added services such as cutting, drilling, and machining to help our customers get the exact product they need. Our team of experienced professionals can work with you to determine the best processing method for your specific application and provide you with a product that meets your exact specifications.

At Huaxia-Steel, we are committed to providing our customers with high-quality carbon steel products and reliable service. Whether you need standard sizes or custom shapes and sizes, we are your trusted source for AISI 1055 Steel/S55C Steel and other carbon steel products. Contact us today to learn more about our available processing options and how we can meet your needs as a carbon steel supplier.

AISI 1055 Steel/S55C Steel Quality Assurance

As a reputable carbon steel supplier, Huaxia-Steel is committed to providing high-quality AISI 1055 Steel/S55C Steel products to our clients worldwide. We understand that quality is of the utmost importance, which is why we adhere to strict quality control standards throughout the production process.

Our AISI 1055 Steel/S55C Steel products are manufactured using top-grade raw materials and the latest manufacturing techniques, ensuring that they meet the highest industry standards. We also employ quality inspectors who conduct rigorous testing to ensure that our products are free from any defects or inconsistencies.

In addition, we have obtained various quality certifications, including ISO 9001:2015, which further proves our commitment to quality. Our clients can trust that when they work with Huaxia-Steel, they will receive high-quality AISI 1055 Steel/S55C Steel products that meet their specific requirements.

We also offer comprehensive after-sales service, and our team of experts is always available to answer any questions or concerns our clients may have. Contact us today to learn more about our quality assurance and how we can meet your AISI 1055 Steel/S55C Steel needs.

Frequently Asked Questions (FAQs)

Yes!

1055 steel is a popular material for sword making due to its toughness and durability. It is a high-carbon steel with a carbon content of 0.50-0.60%, making it a good choice for swords that require a balance between hardness and toughness. However, the quality of the sword ultimately depends on the skill of the swordsmith and the heat treatment process used.

Carbon steel suppliers like us at Huaxia-Steel offer high-quality AISI 1055 steel that is suitable for sword making. It is important to note that the properties of 1055 steel can vary depending on the specific heat treatment used. Therefore, it is important to work with an experienced and skilled swordsmith who can properly heat treat the steel to bring out its full potential.

In conclusion, 1055 steel is a good choice for sword making due to its toughness and durability. However, the quality of the sword depends on the skill of the swordsmith and the heat treatment process used. At Huaxia-Steel, we are committed to providing high-quality carbon steel to our customers for a variety of applications, including sword making.

1055 carbon steel is welded with WEWELDING 600 electrode.

Because 1055 carbon steel is high strength medium carbon steel, after treatment, it has high surface hardness and strength, but its plasticity and toughness are poor, its machinability is medium, its weldability and hardenability are poor, and its water quenching has the tendency to form cracks. When welding, it is necessary to use WEWELDING 600 welding rod with excellent crack resistance to ensure the crack resistance after welding and the tensile strength requirements during use.

Our Services

Customized Design

Tailored solutions to meet your unique needs

Fast Turnaround

Efficient and timely delivery of orders

Quality Assurance

Rigorous testing to ensure high-quality products

Responsive Support

Timely and helpful customer service and technical assistance.

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Huaxia-Steel – carbon steel suppliers will respond within 24 hours to continue the discussion and provide you with any additional information you requires.