A572 Grade 50 Steel Plate - Alloy Steel Suppliers

Product Name:

A572 Grade 50 Steel Plate

Material:

A572 Grade 50 Steel

Category:

alloy steel plate

Supply steel mills:

Baosteel, Anshan Iron and Steel, Meishan Iron and Steel

Storage place:

Shanghai

Breif Introduction:

Huaxia-steel is a professional alloy steel suppliers of A572 Grade 50 Steel Plate with more than ten years of export experiences and timely response within 12 hours. Welcome to send us inquiries directly.

In this page, we will talk about A572 Grade 50 Steel Plate from the following parts:

Contents

Product Introduction

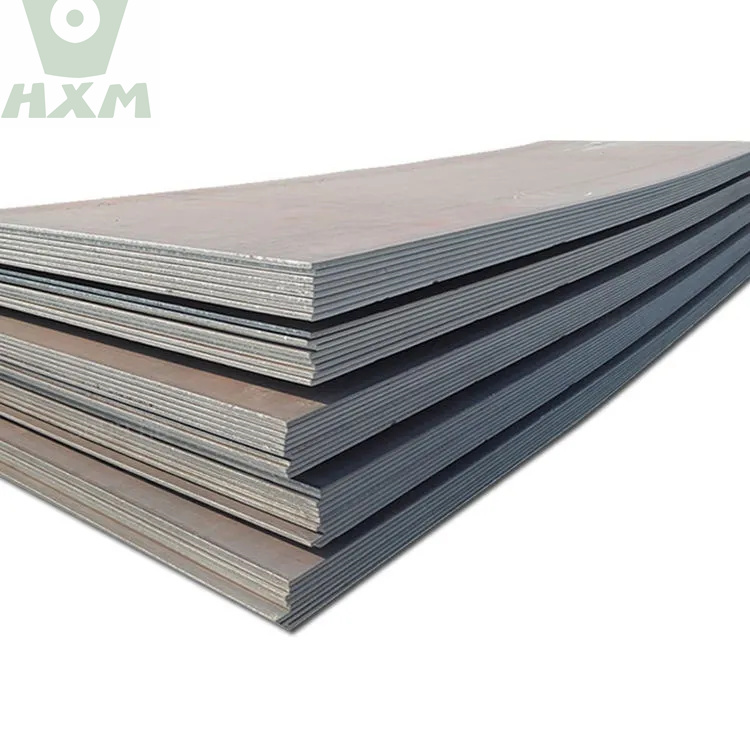

A572 Grade 50 Steel Plate offers excellent strength, toughness, and weldability, making it a versatile and valuable material for use in heavy equipment and structural applications. As a professional B2B steel company and alloy steel suppliers, we provide high-quality products, customized solutions, and exceptional customer service to our clients, ensuring that our A572 Grade 50 Steel Plate is a competitive and valuable product in the market.

Main Features of A572 Grade 50 Steel Plate

A572 Grade 50 Steel Plate is a high-strength, low-alloy steel plate that is widely used in structural applications. Its main features include excellent strength, toughness, and weldability, making it ideal for use in construction and heavy equipment manufacturing.

As a professional B2B steel company and alloy steel suppliers in Shanghai, we understand the importance of providing high-quality products that meet international standards. Our A572 Grade 50 Steel Plate is carefully manufactured to meet the specific requirements of our customers, with a focus on quality control and product consistency.

In addition, we have a team of experienced engineers and technical experts who can provide customized solutions and technical support to our customers. We are committed to providing reliable and efficient services to our clients, and we strive to exceed their expectations with every order.

We take pride in our reputation as trusted alloy steel suppliers of high-quality steel products, and we are confident that our A572 Grade 50 Steel Plate will meet the needs of your professional buyers.

.jpg)

.jpg)

Advantages of A572 Grade 50 Steel Plate

A572 Grade 50 Steel Plate is a high-strength, low-alloy steel plate that offers several advantages over other materials in its class. Its primary advantage is its excellent strength, making it ideal for use in heavy equipment and structural applications.

Additionally, it has excellent toughness, impact resistance, and weldability, making it easier to work with and more versatile in application.

A572 Grade 50 Steel Plate Applications

A572 Grade 50 Steel Plate is widely used in many industries due to its excellent strength, toughness, and weldability. Its applications include heavy equipment, structural components, mining equipment, and transportation equipment.

In the construction industry, A572 Grade 50 Steel Plate is used to build bridges, buildings, and other structures that require high strength and durability. It is also used in the manufacture of cranes, excavators, and other heavy equipment.

In the mining industry, A572 Grade 50 Steel Plate is used to manufacture machinery and equipment that is required to withstand the harsh conditions of mining operations. This includes conveyor systems, drilling equipment, and crushers.

In the transportation industry, A572 Grade 50 Steel Plate is used in the construction of railcars, trailers, and truck frames. Its high strength and toughness make it an ideal material for these applications, as it can withstand heavy loads and harsh conditions.

As professional alloy steel suppliers, we understand the importance of providing high-quality products that meet the needs of our customers. Our A572 Grade 50 Steel Plate is manufactured to international standards and is available in a range of sizes and thicknesses to meet the specific requirements of each application.

A572 Grade 50 Steel Plate Material requirements

A572 Grade 50 Steel Plate is a type of high-strength low-alloy steel material that boasts excellent mechanical properties and corrosion resistance. The material requirements for A572 Grade 50 Steel Plate include a maximum carbon content of 0.23%, a maximum manganese content of 1.35%, and a maximum silicon content of 0.4%.

Additionally, the steel must meet specific standards for yield strength, tensile strength, and elongation at break. These requirements ensure that A572 Grade 50 Steel Plate is of high quality and suitable for use in demanding applications where strength, durability, and corrosion resistance are critical. By meeting these material requirements, our company demonstrates its expertise and commitment to providing customers with top-quality products that meet their needs and exceed their expectations.

A572 Grade 50 Steel Plate Chemical Requirements

| Element | Range, % |

|---|---|

| Carbon (C) | 0.23 – 0.26 |

| Manganese (Mn) | 1.35 – 1.65 |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.05 max |

| Silicon (Si) | 0.15 – 0.40 |

| Copper (Cu) | 0.2 min |

Note that these are the typical chemical requirements for A572 Grade 50 Steel Plate and may vary slightly depending on the manufacturer or specific grade of the steel.

A572 Grade 50 Steel Plate Mechanical Properties‘ Requirements

| Property | Value |

|---|---|

| Tensile strength, ksi (MPa) | 65-95 (450-655) |

| Yield strength, min. ksi (MPa) | 50 (345) |

| Elongation in 8″ (200mm), min. % | 18 |

| Elongation in 2″ (50mm), min. % | 21 |

| Charpy V-notch impact test: | / |

| – Longitudinal (L), ft-lb (J) | 20 (27) at room temperature |

| – Transverse (T), ft-lb (J) | 16 (22) at room temperature |

Note that these values are typical requirements and may vary depending on the specific grade, thickness, and manufacturing process used for the A572 Grade 50 Steel Plate.

The production Process for A572 Grade 50 Steel Plate

The production process for A572 Grade 50 Steel Plate is a complex and precise operation that requires a high level of expertise and attention to detail.

The process starts with the selection of high-quality raw materials, which are then melted and refined in a state-of-the-art furnace. The molten steel is then cast into slabs, which are subsequently rolled into the desired thickness and width using a series of specialized rolling mills.

The rolled plates are then subjected to a rigorous process of heat treatment, which involves heating the steel to a specific temperature and then cooling it rapidly to improve its mechanical properties. Finally, the plates are cut and trimmed to their final dimensions, inspected for quality and compliance with industry standards, and then packaged and shipped to customers worldwide.

As professional alloy steel suppliers, our company has a team of highly skilled and experienced professionals who oversee every step of the production process to ensure that the A572 Grade 50 Steel Plate we manufacture meets the highest standards of quality and performance. We take pride in our ability to deliver products that meet or exceed our customers’ expectations and demonstrate our expertise and commitment to providing them with the best possible solutions to meet their specific needs.

Available Processing Way of A572 Grade 50 Steel Plate

A572 Grade 50 Steel Plate can be processed using various methods, including:

- Cutting:

A572 Grade 50 Steel Plate can be cut to size using plasma, oxy-fuel, or laser cutting. - Forming:

A572 Grade 50 Steel Plate can be formed into various shapes and sizes using processes such as bending, rolling, and press braking. - Welding:

A572 Grade 50 Steel Plate can be welded using various methods, including MIG, TIG, and stick welding. - Machining:

A572 Grade 50 Steel Plate can be machined using conventional methods such as drilling, milling, and turning. - Heat treatment:

A572 Grade 50 Steel Plate can be heat treated to improve its strength and other mechanical properties.

It’s important to note that the specific processing methods used for A572 Grade 50 Steel Plate may vary depending on the manufacturer and the intended application of the steel.

.jpg)

A572 Grade 50 Steel Plate Hot Rolled Stock Specifications

| Thickness (in) | Width (in) | Length (ft) |

|---|---|---|

| 1/4 | 48 – 120 | 96 – 480 |

| 3/8 | 48 – 120 | 96 – 480 |

| 1/2 | 48 – 120 | 96 – 480 |

| 5/8 | 48 – 120 | 96 – 480 |

| 3/4 | 48 – 120 | 96 – 480 |

| 7/8 | 48 – 120 | 96 – 480 |

| 1 | 48 – 120 | 96 – 480 |

| 1 1/8 | 48 – 120 | 96 – 480 |

| 1 1/4 | 48 – 120 | 96 – 480 |

| 1 1/2 | 48 – 120 | 96 – 480 |

| 1 3/4 | 48 – 120 | 96 – 480 |

| 2 | 48 – 120 | 96 – 480 |

| 2 1/4 | 48 – 120 | 96 – 480 |

| 2 1/2 | 48 – 120 | 96 – 480 |

| 2 3/4 | 48 – 120 | 96 – 480 |

| 3 | 48 – 120 | 96 – 480 |

A572 Grade 50 Steel Plate Production Process

The production process for A572 Grade 50 Steel Plate involves several steps to ensure the final product meets the required specifications and standards. The process typically starts with the selection of high-quality raw materials, including alloy steel, which is then melted in a furnace at a high temperature to form a molten steel solution.

The molten steel is then cast into large slabs, which are then hot rolled at a high temperature to form the desired thickness of the steel plate. The hot rolled steel is then coiled and allowed to cool before undergoing further processing, such as heat treatment, surface treatment, and cutting to size.

During the production process, strict quality control measures are put in place to ensure the steel plate meets the required chemical composition, mechanical properties, and dimensional tolerances. These measures include regular sampling and testing of the steel throughout the production process, as well as final inspection and testing of the finished product before it is shipped to customers.

At Huaxia – Steel, as professional alloy steel suppliers, we have a comprehensive quality control system that adheres to international standards to ensure that our A572 Grade 50 Steel Plate meets the highest quality standards. We are committed to providing our customers with reliable, high-quality steel products that meet their specific needs and exceed their expectations.

A572 Grade 50 Steel Plate Process Flow

The manufacturing process of A572 Grade 50 Steel Plate typically involves several stages, each of which is critical in ensuring the quality and performance of the final product. The process begins with the selection of high-quality raw materials, which are then carefully inspected for quality and consistency.

Next, the raw materials are melted and refined in a furnace, using precise temperature and chemical control to ensure optimal composition and properties. The molten steel is then cast into slabs, which are reheated and rolled into the desired thickness and width, using state-of-the-art rolling mills that ensure precise control of temperature, pressure, and other variables.

After rolling, the plates are subjected to a variety of heat treatment processes, including quenching and tempering, to further enhance their strength, toughness, and other properties. The plates are then inspected and tested using a variety of techniques, including ultrasonic testing, to ensure they meet the required standards for quality and performance.

Throughout the manufacturing process, your company implements a comprehensive quality assurance system, which includes regular inspections, testing, and documentation, to ensure that every plate meets the highest standards of quality and performance. By following a rigorous manufacturing process and maintaining a strong quality assurance system, your company can assure buyers of the exceptional quality and reliability of A572 Grade 50 Steel Plate.

.jpg)

.jpg)

A572 Grade 50 Steel Plate Quality Control System

At Huaxia-steel, as professional alloy steel suppliers, we take great pride in our commitment to quality and reliability. To ensure that every A572 Grade 50 Steel Plate we produce meets the highest standards of quality and performance, we implement a comprehensive quality control system throughout the entire manufacturing process.

Starting with the selection of high-quality raw materials, our quality control personnel conduct strict inspections and tests to ensure that the raw materials meet our strict standards for composition and performance.

We use state-of-the-art equipment and technology to monitor and control every aspect of the manufacturing process, from melting and refining the steel to rolling and heat treatment.

During the manufacturing process, our quality control personnel conduct regular inspections and tests to ensure that each plate meets our strict standards for dimensional accuracy, surface quality, mechanical properties, and other performance factors.

We use a variety of testing techniques, including ultrasonic testing, to detect any defects or flaws that could affect the performance of the plate.

Before shipment, every A572 Grade 50 Steel Plate undergoes a final inspection and testing process, which includes a thorough visual inspection, dimensional measurement, and testing for mechanical properties and other performance factors.

We also provide full documentation and traceability, so that buyers can be confident that every plate they receive is of the highest quality and meets all relevant industry standards and specifications.

By implementing a rigorous quality control system and maintaining a commitment to excellence in manufacturing, Huaxia-steel can assure buyers of the exceptional quality and reliability of our A572 Grade 50 Steel Plate.

Our Services

Customized Design

Tailored solutions to meet your unique needs

Fast Turnaround

Efficient and timely delivery of orders

Quality Assurance

Rigorous testing to ensure high-quality products

Responsive Support

Timely and helpful customer service and technical assistance.

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Huaxia-Steel – carbon steel suppliers will respond within 24 hours to continue the discussion and provide you with any additional information you requires.

.jpg)