What is carbon steel made of?

Once upon a time, in a bustling steel mill, a group of curious engineers were discussing the properties of different types of steel. Suddenly, one of them posed a question: “What exactly is carbon steel made of?” The others looked at each other with puzzled expressions, realizing they didn’t have a definitive answer. Intrigued, they set out to learn more about the building blocks of this ubiquitous metal.As they delved deeper into their research, they discovered what is carbon steel made of.

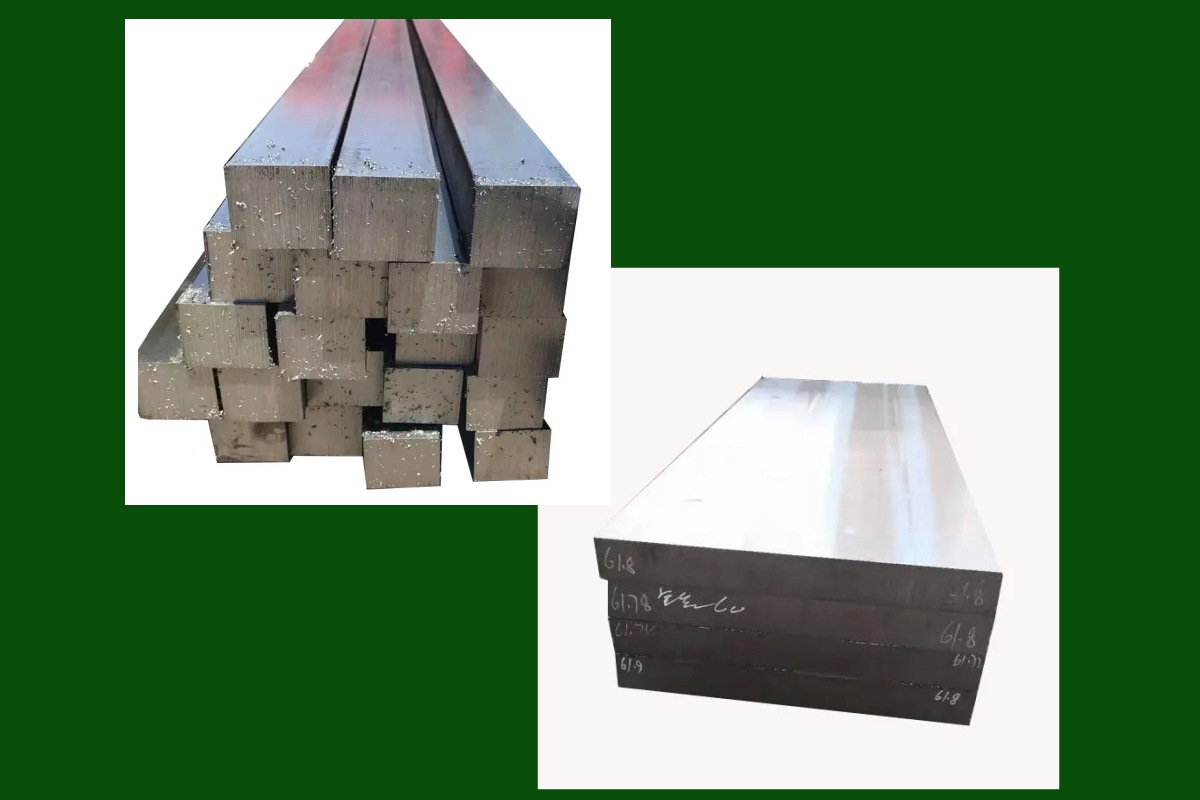

Carbon steel is a type of steel that primarily consists of carbon and iron. Carbon steel typically contains up to 2% carbon by weight, but can also include other elements such as manganese, silicon, and copper. The amount and type of additional elements present in the steel determine its specific properties and uses.

In this article, we will continue to talk about this question:

What are the different grades of carbon steel?

Carbon steel is a broad term used to describe a range of steel alloys that contain varying amounts of carbon. The amount of carbon in the steel affects its properties such as hardness, strength, and ductility. There are several different grades of carbon steel, each with specific properties that make them suitable for different applications. Some of the most common grades include:

- Low carbon steel

- Medium carbon steel

- High carbon steel

- Ultra-high carbon steel

The specific properties of each grade of carbon steel depend on the amount of carbon and other alloying elements such as manganese, silicon, and sulfur. Carbon steel is widely used in construction, automotive, and manufacturing industries due to its strength, durability, and affordability. Choosing the right grade of carbon steel for a particular application requires a thorough understanding of its properties and performance characteristics.

How is carbon steel different from other types of steel?

Carbon steel is a type of steel that contains varying levels of carbon as the main alloying element. Unlike stainless steel, it is not resistant to corrosion and has a lower level of ductility. Carbon steel is also less expensive than stainless steel and is commonly used in construction, automotive, and manufacturing industries. Unlike cast iron, carbon steel is more malleable and easier to work with. Carbon steel can be further classified into four main types: low carbon steel, medium carbon steel, high carbon steel, and ultra-high carbon steel, based on the amount of carbon content present in the material. This material can be easily forged, rolled, and welded into various shapes and forms.

Compared to other types of steel, carbon steel has higher strength, hardness, and toughness, making it suitable for various industrial applications. However, it also has lower ductility and is more prone to rust and corrosion. Carbon steel is commonly used in the production of tools, knives, and blades due to its high carbon content, which makes it durable and long-lasting. Its affordability, malleability, and workability make it a popular choice for a wide range of applications, from structural components to everyday consumer goods.

What are the properties of carbon steel?

Carbon steel is a widely used material due to its desirable properties. It is composed primarily of iron and carbon, with small amounts of other elements. The percentage of carbon in carbon steel can vary from 0.05% to 2.0%, with higher percentages increasing the strength and hardness of the material.

Some of the key properties of carbon steel include its strength, hardness, durability, and ability to be easily shaped and formed. It is also relatively low-cost and widely available, making it a popular choice in many industries. However, carbon steel is prone to rust and corrosion, so proper care and maintenance is necessary to ensure its longevity.

Carbon steel can also be heat-treated to further enhance its properties. This process involves heating the material to a specific temperature and then cooling it rapidly, which can increase its strength and hardness.

Overall, carbon steel is a versatile and widely used material due to its desirable properties and relatively low cost. Its properties can be further enhanced through heat treatment and proper maintenance.

Can carbon steel be hardened?

Yes, carbon steel can be hardened through a process called heat treatment. By heating the steel to a specific temperature and then rapidly cooling it, the carbon atoms become trapped in a specific arrangement, creating a harder and stronger material. The specific temperature and cooling method used will depend on the desired hardness and strength of the final product. It’s important to note that while hardening can increase the strength of carbon steel, it can also make it more brittle, so it’s important to balance the desired properties for the intended application.

What are some common applications of carbon steel?

Carbon steel has a wide range of applications due to its strength, durability, and affordability. It is commonly used in construction, manufacturing, and transportation industries. Carbon steel pipes are used in plumbing and gas pipelines, while sheets and plates are used for construction of buildings, bridges, and machinery. The automobile industry uses carbon steel for the manufacturing of vehicle frames, gears, and axles. Carbon steel is also used in the production of tools, such as knives and drills, due to its hardness and ability to hold a sharp edge. Additionally, it is commonly used in the production of appliances, cookware, and utensils for its resistance to corrosion and ability to withstand high temperatures. The marine industry uses carbon steel for shipbuilding due to its strength and durability in harsh environments. Carbon steel is a versatile material that can be easily fabricated, welded, and machined, making it an ideal choice for a wide range of applications.

How is carbon steel used in construction?

Carbon steel is a popular material in construction due to its strength, durability, and affordability. It is often used in the construction of buildings, bridges, and other structures. Carbon steel’s high strength-to-weight ratio makes it a suitable material for structural applications, where it can provide stability and support.

In construction, carbon steel can be found in various forms, such as beams, columns, plates, and pipes. It is commonly used for framing, as well as in the fabrication of trusses, scaffolding, and other support systems. Carbon steel is also used in the construction of foundations, as it is able to withstand the weight of the building and provide a stable base.

Carbon steel is often coated with protective materials such as paint, zinc, or epoxy to prevent rust and corrosion, which can compromise its structural integrity over time. Additionally, carbon steel can be heat-treated to increase its hardness and durability, making it even more suitable for construction applications.

How is carbon steel used in the manufacturing industry?

Carbon steel is a popular material in the manufacturing industry due to its durability, strength, and affordability. It is commonly used to make various machine components, including gears, bolts, and screws, as well as structural parts, such as beams and plates. Carbon steel is also frequently used to fabricate pipelines, storage tanks, and other equipment for the oil and gas industry.

In the automotive industry, carbon steel is often used to produce car parts such as chassis, engine components, and suspension systems. It is also used in the production of railroad tracks and shipping containers.

One of the primary advantages of carbon steel is its versatility. It can be easily formed, machined, and welded, making it ideal for a wide range of applications. Additionally, carbon steel is readily available and cost-effective compared to other materials, such as stainless steel.

However, carbon steel is susceptible to rust and corrosion, which can compromise its structural integrity over time. To prevent this, manufacturers often apply coatings or use other corrosion-resistant materials in combination with carbon steel in high-risk applications.

What are the advantages of using carbon steel?

Carbon steel has a number of advantages that make it a popular choice in various industries. Firstly, it is relatively low-cost compared to other types of steel, making it an economical choice for many applications. Secondly, it is highly durable and strong, which makes it suitable for use in high-stress applications. Additionally, carbon steel can be easily machined, welded, and fabricated, which makes it a versatile material that can be used for a wide range of products and components. It is also highly resistant to corrosion, which makes it ideal for use in harsh environments.

Another advantage of carbon steel is its ability to be heat-treated to increase its hardness and strength. This makes it suitable for use in applications where high strength and durability are required. Carbon steel is also highly recyclable, which makes it an environmentally friendly choice for many industries.

Overall, the advantages of carbon steel make it a highly versatile and useful material for a wide range of applications, from construction to manufacturing to consumer goods.

How does the carbon content affect the properties of carbon steel?

Carbon steel is an alloy made up of iron and carbon. The carbon content in carbon steel can range from 0.05% to 2.0%. The higher the carbon content, the harder and stronger the steel. Carbon steel with a lower carbon content is softer and more ductile.

The carbon content affects various properties of carbon steel. As mentioned, higher carbon content results in harder and stronger steel, making it ideal for applications requiring high strength and durability. However, higher carbon content can also make the steel more brittle, reducing its toughness and impact resistance.

Lower carbon content results in softer and more ductile steel, which is easier to shape and work with. However, it also makes the steel less strong and durable.

In addition to strength and ductility, carbon content also affects other properties of carbon steel, such as corrosion resistance and machinability. Therefore, selecting the appropriate carbon content for the desired application is important to achieve the desired properties and performance.

Can carbon steel rust?

Yes, carbon steel can rust if it is not properly protected. Carbon steel contains iron, which is prone to rusting when exposed to moisture and oxygen. Rust is a form of corrosion that weakens the steel and can cause it to fail over time.

To prevent rust, carbon steel is often coated with a protective layer, such as paint or a layer of zinc through a process called galvanization. Additionally, stainless steel, which contains a higher amount of chromium, is often used in applications where resistance to corrosion is critical.

It’s important to note that the amount of carbon in the steel can also affect its resistance to corrosion. High carbon content can lead to lower resistance to corrosion, while low carbon content can improve its resistance.

Conclusion

In conclusion, carbon steel is a widely used material in various industries due to its unique properties. The difference in carbon content and other alloying elements gives rise to different grades of carbon steel with varying properties and applications. Carbon steel is distinct from other types of steel due to its relatively low cost, ease of manufacturing, and high strength. Its high tensile strength, durability, and resistance to wear and tear make it suitable for use in construction, automotive, and manufacturing industries.

The carbon content of carbon steel plays a significant role in determining its properties. Higher carbon content leads to greater hardness, strength, and resistance to wear and tear. However, excessive carbon content can lead to brittleness and reduced ductility. Carbon steel can be hardened by heat treatment, quenching, and tempering, making it suitable for cutting tools, springs, and other applications requiring high strength and wear resistance.

Although carbon steel is highly resistant to corrosion, it can rust when exposed to moisture and oxygen. This issue can be addressed by coating the surface with protective coatings or by using corrosion-resistant alloys.

In summary, carbon steel is a versatile material with a wide range of applications due to its unique properties, cost-effectiveness, and ease of manufacturing. Its use in various industries is expected to continue, and ongoing research and development of new grades of carbon steel with enhanced properties are expected to increase its utility and further expand its applications.

Related Blogs

Steel Pipe vs Steel Tube: Key Differences and Applications

Discover the key differences between steel pipes and steel tubes, including their uses, measurements, and schedules like schedule 40 vs schedule 80 pipes. Learn which is right for your project and how to choose the best steel solution.

General Materials of Honed Tubes

Honed tubes are typically made from materials such as carbon steel, alloy steel, stainless steel, and special alloys. Carbon steel, like ST52 and 45#, is widely used for its strength and affordability, making it ideal for hydraulic and pneumatic systems. Alloy steel, including grades like 16Mn and 27SiMn, offers enhanced wear resistance and strength for high-pressure applications. Stainless steel, such as 304 and 316, is favored for its corrosion resistance, especially in harsh environments. Special alloys like Inconel and Hastelloy are used in extreme conditions where high temperatures or corrosion resistance is essential, such as in marine and chemical industries.

The Relationship Between Carbon Steel and Tool Steel

Carbon steel and tool steel are two fundamental types of steel, each with its own specific properties and applications. While they share some similarities—both being forms of steel with varying carbon content—they serve very different purposes in industrial and manufacturing contexts. Understanding the relationship between carbon steel and tool steel can help clarify their unique roles and why each is chosen for specific applications.

Contents

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Our team of experts will respond within 24 hours to continue the discussion and provide you with any additional information you requires.