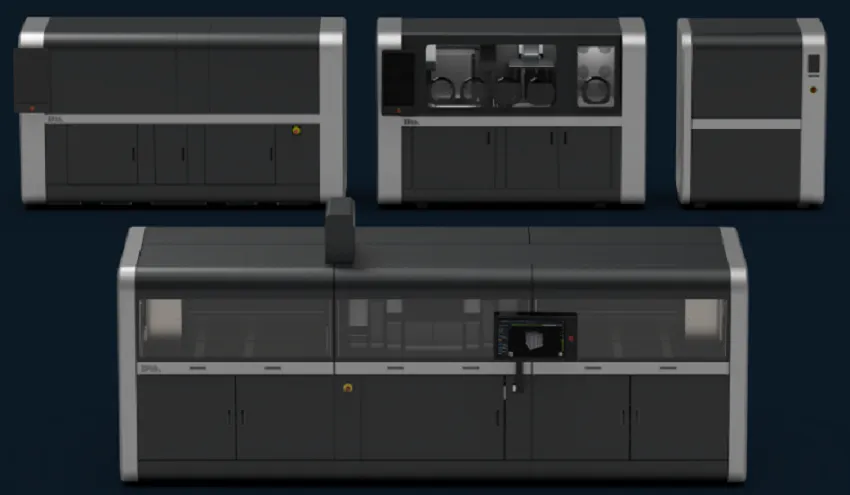

Desktop Metal has completed the certification of Grade 420 Stainless Steel (420 SS) for use in a production system platform utilizing patent-pending Single Pass Jetting TM (SPJ) technology for high-throughput additive manufacturing.

Manufacturers can now utilize SPJ technology to mass produce high-strength end-use parts of 420 stainless steel for demanding applications in industries such as medical, aerospace, defense, and consumer goods.

Overcoming technical difficulties means that the application range of 420 stainless steel is more and more extensive.

420 stainless steel is a martensite stainless steel with the advantages of wear resistance, corrosion resistance and high hardness.

It is the raw material of all kinds of precision machinery, bearings, electrical, equipment, instruments, meters, means of transportation, household appliances and so on.

Desktop Metal’s materials science team produces parts printed at 420 SS on a system platform that eliminates tooling and minimizes material waste. Production time and part cost are significantly reduced compared to traditional manufacturing methods.

420 stainless steel has the advantages of high hardness and strong corrosion resistance. That’s why 420 SS is the ideal material for components such as locking hinge rods.

No tools are required to produce these parts due to the use of adhesive jetting on the production system. So mass production can begin as soon as the design is complete, saving valuable time and money.

420 SS is an essential material in these applications because of its high hardness and corrosion resistance, which ensures long component life and the hardness required to extrude a variety of materials.

The production system material portfolio is not only certified for 420 stainless steel, but also includes nickel alloy IN625, 17-4PH stainless steel, 316L stainless steel and 4140 low alloy steel.

The open systems’ platform also supports a variety of customer-approved materials, including silver and gold. The company plans to introduce more qualified metals in its product portfolio, including tool steels, stainless steels, super alloys, copper and more.

| 420 stainless steel chemical composition | ||||||

| Carbon C | Manganese Mn | Silicon Si | Chromium Cr | Nickel Ni | Phosphorus P | Sulfur S |

| 0.16~0.25 | ≤1.00 | ≤1.00 | 12.0~14.0 | ≤0.75 | ≤0.04 | ≤0.03 |

420 stainless steel mechanical properties

Tensile strength σb (MPa): quenching and tempering, ≥635

Conditional yield strength σ0.2 (MPa): quenching and tempering, ≥440

Elongation δ5 (%): quenching and tempering, ≥20

Area shrinkage ψ (%): quenching and tempering, ≥50

Impact energy Akv (J): quenching and tempering, ≥63

Hardness: annealed, ≤223HB; quenched and tempered, ≥192HB

The difference between 420 stainless steel and 304 stainless steel

1) The application range is different

420 stainless steel is suitable for all kinds of precision machinery, bearings, electrical, equipment, instruments, meters, transportation tools, household appliances, etc.

It is mostly used to manufacture parts that are resistant to atmospheric, water vapor, water and oxidative acid corrosion.

304 stainless steel is a common material in stainless steel and is widely used in industrial and furniture decoration industries and food and medical industries.

2) Different characteristics

420 stainless steel is a martensite stainless steel with certain wear resistance and corrosion resistance, high hardness and other characteristics;

304 stainless steel has good corrosion resistance, heat resistance, low temperature strength and mechanical properties; good hot workability such as stamping and bending, no heat treatment hardening phenomenon, corrosion resistance in the atmosphere.

If you would like to know more, please ask our customer service.