In the field of modern engineering machinery, shock absorbers, as equipment that absorbs energy and slows down mechanical vibrations, play a vital role in ensuring the stability and safety of the structure. As a common engineering material, carbon steel is widely used in shock-absorbing devices due to its high strength, good toughness and cost-effectiveness. Today’s article introduces in detail the application of carbon steel in shock absorbing devices.

Application of Carbon Steel in Shock Absorbing Devices:

First of all, in terms of strength and hardness. Since shock-absorbing devices need to absorb and disperse energy instantaneously to reduce the impact of vibrations on structures, this requires materials to have sufficient strength and durability. Carbon steel, as a high-performance alloy steel, is able to withstand relatively large loads and impacts, making it an ideal material for the supporting structure of shock absorbers. For instance, in automotive suspension systems, the supporting structure of carbon steel shock absorbers can effectively reduce vibrations and impacts caused by various road conditions, enhancing the ride comfort of vehicles.

Secondly, in terms of toughness and ductility. Carbon steel’s good toughness and ductility enable it to undergo a certain degree of plastic deformation when subjected to vibrations or high-pressure impacts, thus further absorbing and dissipating energy. Compared to brittle materials, carbon steel is less prone to sudden fractures during shock absorption, improving the reliability of shock-absorbing devices. It is often used in the manufacture of shock-absorbing components in machinery, automobiles, and other structures.

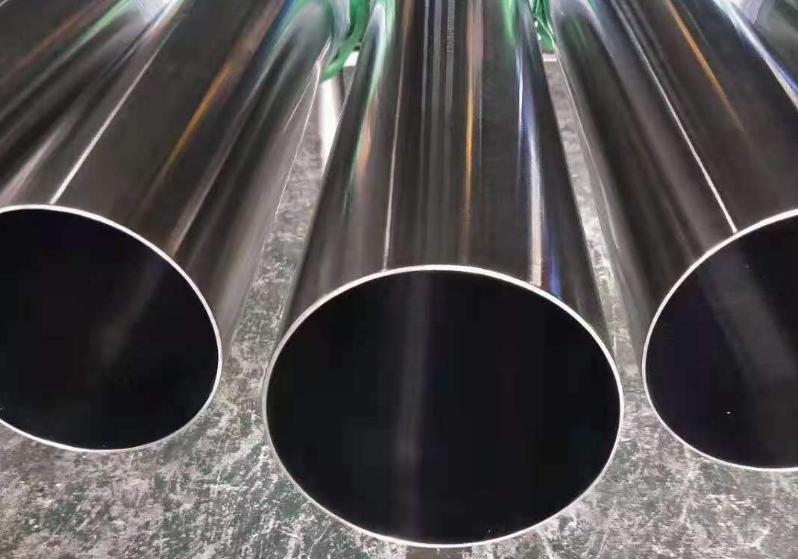

Moreover, in terms of processability. Carbon steel boasts good processing properties and mature processing techniques, which allows for effective cost control in the large-scale production of shock-absorbing devices. Additionally, through rational design and heat treatment processes, carbon steel can be processed into various shapes and sizes, adapting to scenarios with different shock-absorbing needs. It is commonly used to manufacture various damping components, such as damping rods and damping sheets.

Lastly, in terms of cost-effectiveness. Compared to other high-performance alloy materials, carbon steel has certain limitations in corrosion resistance, such as being prone to corrosion in humid environments, which can reduce its performance and service life. However, the lower cost of carbon steel helps reduce manufacturing costs, allowing it to occupy an important position in shock-absorbing devices due to its comprehensive advantages.

Conclusion

In conclusion, carbon steel plays an indispensable role in shock-absorbing devices due to its strength, toughness, cost-effectiveness, and processability. However, the application of carbon steel in shock-absorbing devices is not without challenges. With the continuous development of material science and engineering technology, carbon steel materials need to be constantly optimized and innovated to provide robust support for building safer and more stable engineering structures.

Why Choose Huaxia Steel?

Thank you for reading our article and we hope it can help you to have a better understanding of the application of carbon steel in shock absorbing devices. If you are looking for carbon steel suppliers and manufacturers online now, we would advise you to visit Huaxia Steel.

As a leading supplier of carbon steel products from Shanghai China, Huaxia Steel offers customers high-quality carbon steel tubes, carbon steel bars and carbon steel plates at a very competitive price.