density of carbon steel

The density of carbon steel is approximately 7.85 g/cm³ (7850 kg/m³), though it can vary slightly depending on the specific composition and carbon content. Carbon steel, primarily made of iron with a carbon content between 0.05% and 2.1%, is widely used for its strength and durability. Its density significantly influences its weight and mechanical properties, making it ideal for applications in construction, automotive, and machinery manufacturing. Understanding the density of carbon steel is essential when designing projects that require a balance between strength and weight, ensuring optimal performance in various engineering fields.

In this article, we’ll explore the density of carbon steel and how it affects its properties and applications.

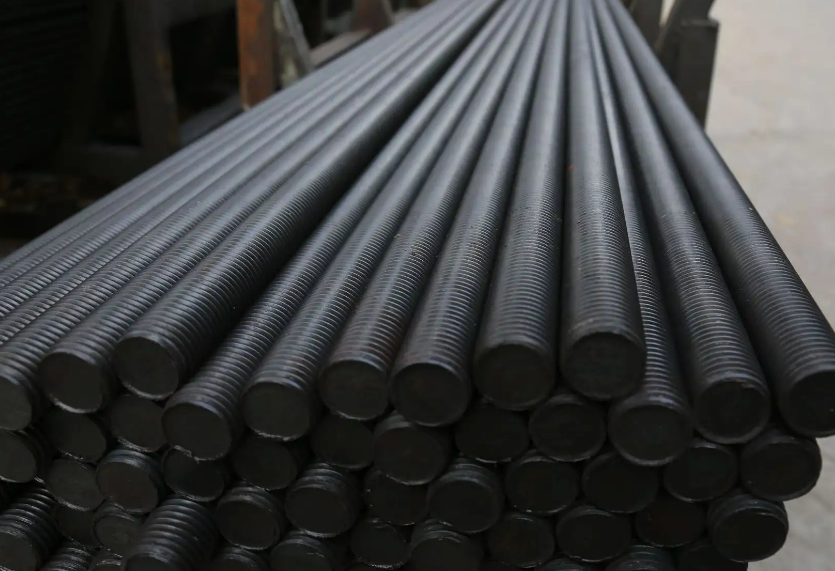

Carbon steel is a sturdy material, mainly composed of iron and carbon, with small amounts of other elements. Due to its durability and strength, it is widely used in various industries. Different grades of carbon steel have different carbon contents. Higher carbon content can increase hardness and strength, but high-carbon steel is fragile and challenging to use.

Carbon steel is widely used in construction, automotive manufacturing, and mechanical production. It is used to make metal products such as tools and cutlery. Carbon steel’s low cost and ease of processing make it a popular choice for the manufacturing industry.

However, if not handled or coated correctly, carbon steel can rust and corrode. It is a versatile material that can be easily welded and shaped.

What is the Density of Carbon Steel?

The density of pure carbon steel is approximately 7.8 g/cm3 (0.284 lb/in3). However, the density can vary due to the presence of alloying elements, ranging from 7.75 g/cm3 (0.282 lb/in3) to 8.05 g/cm3 (0.291 lb/in3). Compared with other metals such as stainless steel and copper alloys, carbon steel is generally lighter, but heavier than aluminum.

How does density affect carbon steel properties?

The density of carbon steel has a significant impact on its properties. Firstly, the density of carbon steel determines its strength and hardness. Generally, carbon steel with higher density exhibits better strength and hardness. This is because the iron atoms in high-density carbon steel are more closely packed, resulting in stronger interatomic forces.

Secondly, the density also affects the toughness and ductility of carbon steel. Higher density typically leads to lower toughness and ductility, as the atoms in high-density carbon steel are more ordered, making the material more prone to brittle fracture when subjected to external forces.

Furthermore, the density can affect the corrosion resistance of carbon steel. High-density carbon steel exhibits better corrosion resistance as its surface is less prone to the formation of oxide layers, while low-density carbon steel is more susceptible to corrosion.

In summary, the density of carbon steel plays an important role in its properties. When selecting and using carbon steel, it is essential to choose the appropriate density based on its intended use and performance requirements.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the density of carbon steel. If you want to find more information about carbon steel, we’d advise you to visit Huaxia Steel.

As a leading supplier of carb steel products across the world, Huaxia Steel provides customers with high-quality such as alloy steel, tool steel, and carbon steel pipes for global markets.