Does carbon steel work on induction?

Carbon steel is a common material used in various industries, from construction to kitchenware. However, when it comes to induction cooking, not all materials are created equal. Let me tell you a story about a home cook who invested in an induction cooktop, only to find that their trusty carbon steel pan wouldn’t work on it. Frustrated and confused, they set out to understand the science behind induction and the best materials to use.

Carbon steel can work on induction, but it depends on the magnetic field strength. Carbon steel must contain sufficient amounts of iron to generate a magnetic field and be responsive to the induction technology. However, carbon steel is not as effective as other materials like stainless steel or cast iron in terms of heat distribution and retention.

In this article, we’ll explore this topic. Let’s dive in and uncover the truth about carbon steel and induction.

Table of Contents

I. Introduction

Carbon steel is a popular material used in many industries, including construction, manufacturing, and transportation. Its excellent strength and durability make it a preferred choice for a wide range of applications. However, the question that often arises is whether carbon steel works on induction heating. In this article, we will explore this question in detail and provide insights for carbon steel suppliers and other stakeholders in the industry.

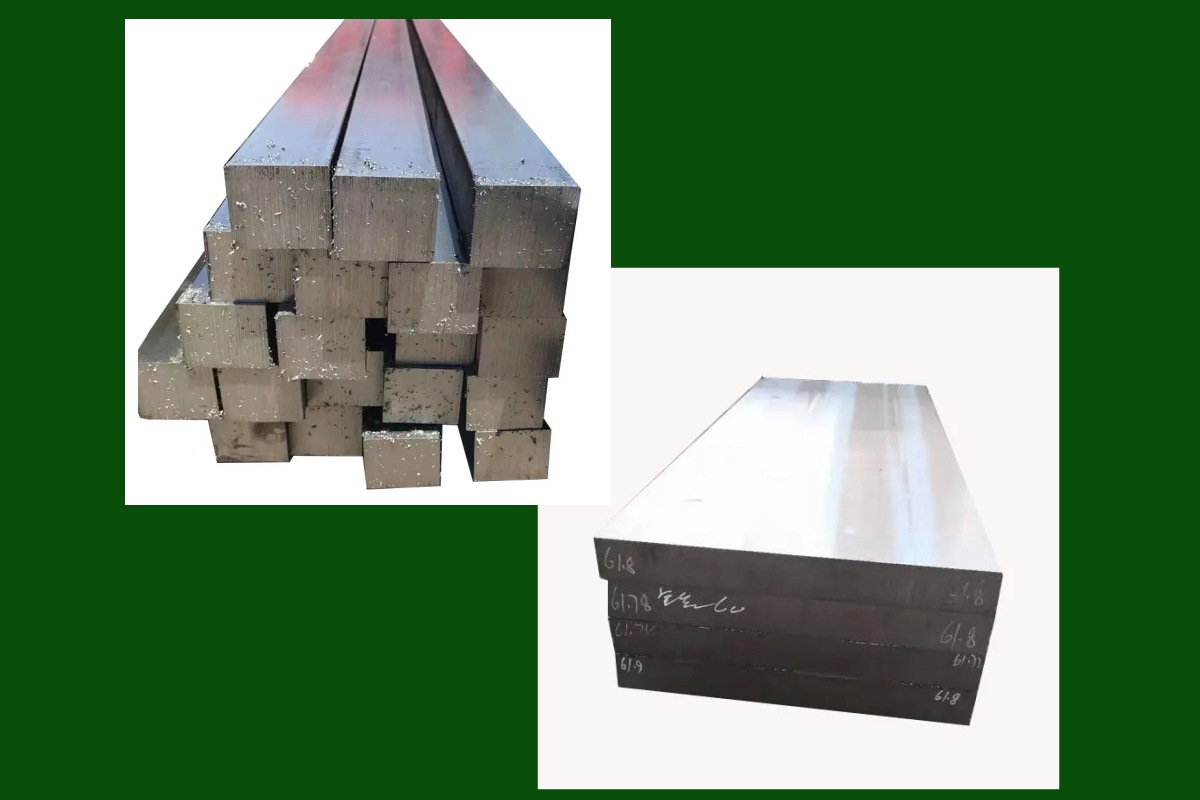

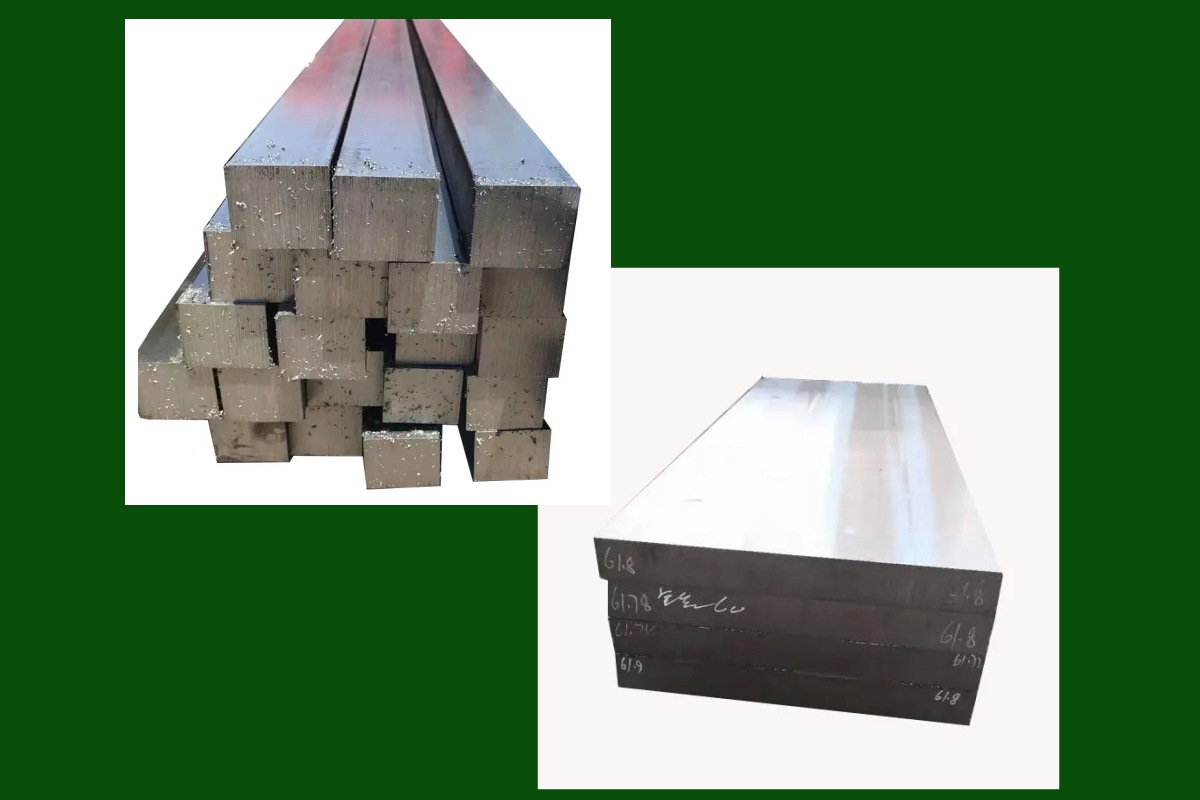

⭐ A. Brief overview of carbon steel and its properties

Carbon steel is a type of steel that contains carbon as the main alloying element. The carbon content in carbon steel typically ranges from 0.05% to 2.0%, making it an affordable and versatile material. Its properties can vary depending on the carbon content and other elements, such as manganese, phosphorus, and sulfur. Carbon steel is known for its strength, hardness, and toughness.

⭐ B. Explanation of induction heating and its applications

Induction heating is a process of heating a conductive material by using an alternating magnetic field. The process involves placing the material inside a coil and passing an alternating electric current through it. The magnetic field generated by the coil induces an electric current in the material, which generates heat. Induction heating is used in many applications, including welding, brazing, forging, and annealing.

⭐ C. Discussion of how carbon steel responds to induction heating

When carbon steel is subjected to induction heating, the magnetic field generated by the coil induces eddy currents in the material. The eddy currents generate heat, which causes the material to reach its melting point. However, the response of carbon steel to induction heating can vary depending on several factors, which we will discuss in detail in the next section.

⭐ D. Importance of carbon steel suppliers in the industry

Carbon steel suppliers play a critical role in the industry by providing high-quality materials that meet the requirements of their customers. They are responsible for ensuring that the carbon steel they supply is suitable for the intended application and meets the required specifications. Therefore, it is essential for carbon steel suppliers to have a good understanding of how their products work in various processes, including induction heating.

⭐ E. Significance of understanding whether carbon steel works on induction

The ability of carbon steel to work on induction heating has significant implications for its use in various applications. If carbon steel can be effectively heated using induction, it can offer several advantages, such as faster heating times, improved energy efficiency, and reduced distortion. Therefore, it is essential to understand the factors that affect the induction heating of carbon steel and the applications in which it can be used.

In the next section, we will explore the composition of carbon steel and how it responds to induction heating in more detail.

II. Understanding Carbon Steel and Induction Heating

⭐ A. Overview of carbon steel and its composition

Carbon steel is a type of steel that is composed mainly of iron and carbon, with trace amounts of other elements. The carbon content of carbon steel can range from 0.05% to 2.0%, with the higher carbon content providing greater strength and hardness. Other elements, such as manganese, phosphorus, and sulfur, can also be added to improve the properties of carbon steel.

⭐ B. Explanation of induction heating and how it works

As mentioned earlier, induction heating is a process of heating a conductive material by using an alternating magnetic field. The process involves passing an alternating electric current through a coil, which generates a magnetic field. When a conductive material, such as carbon steel, is placed inside the coil, the magnetic field induces an electric current in the material. This electric current generates heat in the material, which can be used for various applications.

⭐ C. Discussion of how carbon steel responds to induction heating

Carbon steel can be effectively heated using induction heating, but the response of carbon steel to induction heating can vary depending on several factors. One important factor is the carbon content of the steel. Steel with a higher carbon content responds better to induction heating than steel with a lower carbon content. Other factors that can affect the response of carbon steel to induction heating include the thickness of the steel, the composition of the steel, and the frequency and power output of the induction heater.

⭐ D. Importance of understanding carbon steel and induction heating for carbon steel suppliers

Carbon steel suppliers play a crucial role in the industry by providing high-quality materials that meet the requirements of their customers. Therefore, it is essential for carbon steel suppliers to have a good understanding of how their products respond to various processes, including induction heating. By understanding the factors that affect the response of carbon steel to induction heating, carbon steel suppliers can provide their customers with materials that are suitable for their intended applications.

⭐ E. Advantages of using induction heating on carbon steel

Induction heating offers several advantages for heating carbon steel. One advantage is that it provides faster heating times than other heating methods, such as gas or electric heating. Induction heating also offers improved energy efficiency, which can result in cost savings for carbon steel suppliers and their customers. Additionally, induction heating can reduce distortion in the material, which is important for applications where dimensional accuracy is critical.

In the next section, we will discuss the factors that affect induction heating of carbon steel in more detail.

III. Factors that Affect Induction Heating of Carbon Steel

Induction heating is a versatile and efficient process that can be used on various materials, including carbon steel. However, several factors can affect the induction heating process and its effectiveness on carbon steel. Here are some of the factors to consider:

⭐ A. Thickness of the carbon steel:

The thickness of the carbon steel can significantly affect the induction heating process. Thicker sections may require higher power output and longer heating times to achieve the desired results. Carbon steel suppliers can provide guidance on the appropriate thickness for a given application.

⭐ B. Composition of the carbon steel:

The chemical composition of the carbon steel can also affect its response to induction heating. Carbon steel with a higher carbon content, for example, may require more power to heat effectively. Carbon steel suppliers can provide information on the specific composition of their products.

⭐ C. Frequency of the induction heater:

The frequency of the induction heater can also affect the heating process. Higher frequencies are generally more effective for heating thinner sections of carbon steel, while lower frequencies are better for thicker sections.

⭐ D. Power output of the induction heater

The power output of the induction heater should be carefully chosen to match the thickness and composition of the carbon steel being heated. Too little power output may result in ineffective heating, while too much power output can cause damage to the material.

⭐ E. Cooling rate of the carbon steel

The cooling rate of the carbon steel after induction heating can affect its final properties. Slow cooling rates can result in softer material, while rapid cooling rates can result in harder, more brittle material.

Carbon steel suppliers can provide information and guidance on the appropriate factors to consider for a given application. By carefully controlling these factors, it is possible to achieve the desired results when using induction heating on carbon steel.

Overall, while there are several factors to consider when using induction heating on carbon steel, it remains a versatile and effective process. Carbon steel suppliers can provide guidance and information to ensure that the process is successful and produces high-quality results.

IV. Applications of Carbon Steel Induction Heating

⭐ A. Advantages of using induction heating on carbon steel

Induction heating has several advantages when used on carbon steel. It provides fast and efficient heating, which can save time and energy compared to other heating methods. Induction heating can also produce a uniform heat, resulting in consistent and predictable results. Additionally, it can be used for localized heating, making it ideal for certain applications.

⭐ B. Common applications of induction heating on carbon steel

Induction heating is used in a variety of applications on carbon steel. Some common applications include annealing, hardening, and brazing. Annealing is a heat treatment process that can improve the ductility and toughness of carbon steel. Hardening is a process that can make the steel harder and more resistant to wear and tear. Brazing is a process used to join two pieces of metal together.

⭐ C. Case studies of successful applications of induction heating on carbon steel

There are many successful examples of induction heating being used on carbon steel. For example, in the automotive industry, induction heating is used to harden gears and other components. In the aerospace industry, induction heating is used to heat-treat turbine blades. In the construction industry, induction heating is used to weld reinforcing bars together.

Carbon steel suppliers can provide information on the specific applications of induction heating on their products. They can also provide guidance on the appropriate heating parameters to achieve the desired results.

⭐ D. Limitations of induction heating on carbon steel

While induction heating is a versatile and effective process, there are some limitations to its use on carbon steel.

For example, it may not be suitable for heating large or complex shapes. It may also not be suitable for certain types of carbon steel, such as those with a low carbon content.

Overall, induction heating is a valuable tool for working with carbon steel. It offers several advantages over other heating methods, and its use is widespread across a variety of industries. Carbon steel suppliers can provide guidance and support for using induction heating on their products, ensuring that it is done safely and effectively.

IV. Applications of Carbon Steel Induction Heating

In this article, we have explored the topic of carbon steel and its response to induction heating. We began with an overview of carbon steel and its properties, followed by an explanation of induction heating and its applications. We then delved into how carbon steel responds to induction heating, discussing factors such as thickness, composition, frequency, power output, and cooling rate.

We also discussed the advantages of using induction heating on carbon steel, including its efficiency, speed, and precise heating capabilities. We explored common applications of induction heating on carbon steel, such as hardening, tempering, and annealing, and shared case studies of successful applications in various industries.

In conclusion, carbon steel is an excellent candidate for induction heating, offering a range of benefits over other heating methods. However, it is important to consider the factors that can affect its response to induction heating, as well as the specific application and desired outcome.

Carbon steel suppliers should take into account the unique properties of their products when considering induction heating as a potential processing method. Working with experienced and knowledgeable heat treatment professionals can help ensure successful outcomes.

When using induction heating on carbon steel, we recommend considering the following:

Determine the specific requirements of the application and select the appropriate induction heating method and parameters.

Pay attention to the composition and thickness of the carbon steel, as well as the cooling rate, to ensure the desired outcome.

Work with experienced professionals who have knowledge of induction heating and carbon steel properties to achieve the best results.

Continuously monitor the process to ensure quality and consistency.

With careful consideration and proper execution, induction heating can be a highly effective method for processing carbon steel, offering improved efficiency, accuracy, and control.

Related Blogs

Steel Pipe vs Steel Tube: Key Differences and Applications

Discover the key differences between steel pipes and steel tubes, including their uses, measurements, and schedules like schedule 40 vs schedule 80 pipes. Learn which is right for your project and how to choose the best steel solution.

General Materials of Honed Tubes

Honed tubes are typically made from materials such as carbon steel, alloy steel, stainless steel, and special alloys. Carbon steel, like ST52 and 45#, is widely used for its strength and affordability, making it ideal for hydraulic and pneumatic systems. Alloy steel, including grades like 16Mn and 27SiMn, offers enhanced wear resistance and strength for high-pressure applications. Stainless steel, such as 304 and 316, is favored for its corrosion resistance, especially in harsh environments. Special alloys like Inconel and Hastelloy are used in extreme conditions where high temperatures or corrosion resistance is essential, such as in marine and chemical industries.

The Relationship Between Carbon Steel and Tool Steel

Carbon steel and tool steel are two fundamental types of steel, each with its own specific properties and applications. While they share some similarities—both being forms of steel with varying carbon content—they serve very different purposes in industrial and manufacturing contexts. Understanding the relationship between carbon steel and tool steel can help clarify their unique roles and why each is chosen for specific applications.

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Our team of experts will respond within 24 hours to continue the discussion and provide you with any additional information you requires.

Does carbon steel work on induction?

Carbon steel is a common material used in various industries, from construction to kitchenware. However, when it comes to induction cooking, not all materials are created equal. Let me tell you a story about a home cook who invested in an induction cooktop, only to find that their trusty carbon steel pan wouldn’t work on it. Frustrated and confused, they set out to understand the science behind induction and the best materials to use.

Carbon steel can work on induction, but it depends on the magnetic field strength. Carbon steel must contain sufficient amounts of iron to generate a magnetic field and be responsive to the induction technology. However, carbon steel is not as effective as other materials like stainless steel or cast iron in terms of heat distribution and retention.

In this article, we’ll explore this topic. Let’s dive in and uncover the truth about carbon steel and induction.

Table of Contents

I. Introduction

Carbon steel is a popular material used in many industries, including construction, manufacturing, and transportation. Its excellent strength and durability make it a preferred choice for a wide range of applications. However, the question that often arises is whether carbon steel works on induction heating. In this article, we will explore this question in detail and provide insights for carbon steel suppliers and other stakeholders in the industry.

⭐ A. Brief overview of carbon steel and its properties

Carbon steel is a type of steel that contains carbon as the main alloying element. The carbon content in carbon steel typically ranges from 0.05% to 2.0%, making it an affordable and versatile material. Its properties can vary depending on the carbon content and other elements, such as manganese, phosphorus, and sulfur. Carbon steel is known for its strength, hardness, and toughness.

⭐ B. Explanation of induction heating and its applications

Induction heating is a process of heating a conductive material by using an alternating magnetic field. The process involves placing the material inside a coil and passing an alternating electric current through it. The magnetic field generated by the coil induces an electric current in the material, which generates heat. Induction heating is used in many applications, including welding, brazing, forging, and annealing.

⭐ C. Discussion of how carbon steel responds to induction heating

When carbon steel is subjected to induction heating, the magnetic field generated by the coil induces eddy currents in the material. The eddy currents generate heat, which causes the material to reach its melting point. However, the response of carbon steel to induction heating can vary depending on several factors, which we will discuss in detail in the next section.

⭐ D. Importance of carbon steel suppliers in the industry

Carbon steel suppliers play a critical role in the industry by providing high-quality materials that meet the requirements of their customers. They are responsible for ensuring that the carbon steel they supply is suitable for the intended application and meets the required specifications. Therefore, it is essential for carbon steel suppliers to have a good understanding of how their products work in various processes, including induction heating.

⭐ E. Significance of understanding whether carbon steel works on induction

The ability of carbon steel to work on induction heating has significant implications for its use in various applications. If carbon steel can be effectively heated using induction, it can offer several advantages, such as faster heating times, improved energy efficiency, and reduced distortion. Therefore, it is essential to understand the factors that affect the induction heating of carbon steel and the applications in which it can be used.

In the next section, we will explore the composition of carbon steel and how it responds to induction heating in more detail.

II. Understanding Carbon Steel and Induction Heating

⭐ A. Overview of carbon steel and its composition

Carbon steel is a type of steel that is composed mainly of iron and carbon, with trace amounts of other elements. The carbon content of carbon steel can range from 0.05% to 2.0%, with the higher carbon content providing greater strength and hardness. Other elements, such as manganese, phosphorus, and sulfur, can also be added to improve the properties of carbon steel.

⭐ B. Explanation of induction heating and how it works

As mentioned earlier, induction heating is a process of heating a conductive material by using an alternating magnetic field. The process involves passing an alternating electric current through a coil, which generates a magnetic field. When a conductive material, such as carbon steel, is placed inside the coil, the magnetic field induces an electric current in the material. This electric current generates heat in the material, which can be used for various applications.

⭐ C. Discussion of how carbon steel responds to induction heating

Carbon steel can be effectively heated using induction heating, but the response of carbon steel to induction heating can vary depending on several factors. One important factor is the carbon content of the steel. Steel with a higher carbon content responds better to induction heating than steel with a lower carbon content. Other factors that can affect the response of carbon steel to induction heating include the thickness of the steel, the composition of the steel, and the frequency and power output of the induction heater.

⭐ D. Importance of understanding carbon steel and induction heating for carbon steel suppliers

Carbon steel suppliers play a crucial role in the industry by providing high-quality materials that meet the requirements of their customers. Therefore, it is essential for carbon steel suppliers to have a good understanding of how their products respond to various processes, including induction heating. By understanding the factors that affect the response of carbon steel to induction heating, carbon steel suppliers can provide their customers with materials that are suitable for their intended applications.

⭐ E. Advantages of using induction heating on carbon steel

Induction heating offers several advantages for heating carbon steel. One advantage is that it provides faster heating times than other heating methods, such as gas or electric heating. Induction heating also offers improved energy efficiency, which can result in cost savings for carbon steel suppliers and their customers. Additionally, induction heating can reduce distortion in the material, which is important for applications where dimensional accuracy is critical.

In the next section, we will discuss the factors that affect induction heating of carbon steel in more detail.

III. Factors that Affect Induction Heating of Carbon Steel

Induction heating is a versatile and efficient process that can be used on various materials, including carbon steel. However, several factors can affect the induction heating process and its effectiveness on carbon steel. Here are some of the factors to consider:

⭐ A. Thickness of the carbon steel:

The thickness of the carbon steel can significantly affect the induction heating process. Thicker sections may require higher power output and longer heating times to achieve the desired results. Carbon steel suppliers can provide guidance on the appropriate thickness for a given application.

⭐ B. Composition of the carbon steel:

The chemical composition of the carbon steel can also affect its response to induction heating. Carbon steel with a higher carbon content, for example, may require more power to heat effectively. Carbon steel suppliers can provide information on the specific composition of their products.

⭐ C. Frequency of the induction heater:

The frequency of the induction heater can also affect the heating process. Higher frequencies are generally more effective for heating thinner sections of carbon steel, while lower frequencies are better for thicker sections.

⭐ D. Power output of the induction heater

The power output of the induction heater should be carefully chosen to match the thickness and composition of the carbon steel being heated. Too little power output may result in ineffective heating, while too much power output can cause damage to the material.

⭐ E. Cooling rate of the carbon steel

The cooling rate of the carbon steel after induction heating can affect its final properties. Slow cooling rates can result in softer material, while rapid cooling rates can result in harder, more brittle material.

Carbon steel suppliers can provide information and guidance on the appropriate factors to consider for a given application. By carefully controlling these factors, it is possible to achieve the desired results when using induction heating on carbon steel.

Overall, while there are several factors to consider when using induction heating on carbon steel, it remains a versatile and effective process. Carbon steel suppliers can provide guidance and information to ensure that the process is successful and produces high-quality results.

IV. Applications of Carbon Steel Induction Heating

⭐ A. Advantages of using induction heating on carbon steel

Induction heating has several advantages when used on carbon steel. It provides fast and efficient heating, which can save time and energy compared to other heating methods. Induction heating can also produce a uniform heat, resulting in consistent and predictable results. Additionally, it can be used for localized heating, making it ideal for certain applications.

⭐ B. Common applications of induction heating on carbon steel

Induction heating is used in a variety of applications on carbon steel. Some common applications include annealing, hardening, and brazing. Annealing is a heat treatment process that can improve the ductility and toughness of carbon steel. Hardening is a process that can make the steel harder and more resistant to wear and tear. Brazing is a process used to join two pieces of metal together.

⭐ C. Case studies of successful applications of induction heating on carbon steel

There are many successful examples of induction heating being used on carbon steel. For example, in the automotive industry, induction heating is used to harden gears and other components. In the aerospace industry, induction heating is used to heat-treat turbine blades. In the construction industry, induction heating is used to weld reinforcing bars together.

Carbon steel suppliers can provide information on the specific applications of induction heating on their products. They can also provide guidance on the appropriate heating parameters to achieve the desired results.

⭐ D. Limitations of induction heating on carbon steel

While induction heating is a versatile and effective process, there are some limitations to its use on carbon steel.

For example, it may not be suitable for heating large or complex shapes. It may also not be suitable for certain types of carbon steel, such as those with a low carbon content.

Overall, induction heating is a valuable tool for working with carbon steel. It offers several advantages over other heating methods, and its use is widespread across a variety of industries. Carbon steel suppliers can provide guidance and support for using induction heating on their products, ensuring that it is done safely and effectively.

IV. Applications of Carbon Steel Induction Heating

In this article, we have explored the topic of carbon steel and its response to induction heating. We began with an overview of carbon steel and its properties, followed by an explanation of induction heating and its applications. We then delved into how carbon steel responds to induction heating, discussing factors such as thickness, composition, frequency, power output, and cooling rate.

We also discussed the advantages of using induction heating on carbon steel, including its efficiency, speed, and precise heating capabilities. We explored common applications of induction heating on carbon steel, such as hardening, tempering, and annealing, and shared case studies of successful applications in various industries.

In conclusion, carbon steel is an excellent candidate for induction heating, offering a range of benefits over other heating methods. However, it is important to consider the factors that can affect its response to induction heating, as well as the specific application and desired outcome.

Carbon steel suppliers should take into account the unique properties of their products when considering induction heating as a potential processing method. Working with experienced and knowledgeable heat treatment professionals can help ensure successful outcomes.

When using induction heating on carbon steel, we recommend considering the following:

Determine the specific requirements of the application and select the appropriate induction heating method and parameters.

Pay attention to the composition and thickness of the carbon steel, as well as the cooling rate, to ensure the desired outcome.

Work with experienced professionals who have knowledge of induction heating and carbon steel properties to achieve the best results.

Continuously monitor the process to ensure quality and consistency.

With careful consideration and proper execution, induction heating can be a highly effective method for processing carbon steel, offering improved efficiency, accuracy, and control.

Related Blogs

Steel Pipe vs Steel Tube: Key Differences and Applications

Discover the key differences between steel pipes and steel tubes, including their uses, measurements, and schedules like schedule 40 vs schedule 80 pipes. Learn which is right for your project and how to choose the best steel solution.

General Materials of Honed Tubes

Honed tubes are typically made from materials such as carbon steel, alloy steel, stainless steel, and special alloys. Carbon steel, like ST52 and 45#, is widely used for its strength and affordability, making it ideal for hydraulic and pneumatic systems. Alloy steel, including grades like 16Mn and 27SiMn, offers enhanced wear resistance and strength for high-pressure applications. Stainless steel, such as 304 and 316, is favored for its corrosion resistance, especially in harsh environments. Special alloys like Inconel and Hastelloy are used in extreme conditions where high temperatures or corrosion resistance is essential, such as in marine and chemical industries.

The Relationship Between Carbon Steel and Tool Steel

Carbon steel and tool steel are two fundamental types of steel, each with its own specific properties and applications. While they share some similarities—both being forms of steel with varying carbon content—they serve very different purposes in industrial and manufacturing contexts. Understanding the relationship between carbon steel and tool steel can help clarify their unique roles and why each is chosen for specific applications.

Request A Free Quote

We’d like to work with you

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Our team of experts will respond within 24 hours to continue the discussion and provide you with any additional information you requires.