Many of our customers have such a question: “High Carbon Steel vs Ferrous Metals: What’s the difference?” In today’s article, we’ll delve into the differences between high-carbon steel and ferrous metals, two materials that are often confused but have distinct properties and applications.

High Carbon Steel vs Ferrous Metals: What’s the Difference?

High Carbon Steel vs Ferrous Metals – 1. Definition

High carbon steel is a type of steel that has a carbon content ranging from 0.6% to 1.7% by weight. This relatively high carbon content gives high carbon steel its unique properties.

Ferrous metals, on the other hand, are metals that contain iron as their primary element. This includes pure iron, as well as iron alloys like steel and cast iron.

High Carbon Steel vs Ferrous Metals – 2. Properties

Properties of High Carbon Steel:

- Hardness and Strength: High carbon steel is significantly harder and stronger than low-carbon steel. This makes it ideal for applications that require high wear resistance and durability.

- ** Brittleness:** However, the increased carbon content also makes high carbon steel more brittle. This brittleness can limit its use in certain applications where flexibility or ductility is essential.

- Machinability: High carbon steel is generally more difficult to machine than lower-carbon steels due to its hardness.

- Corrosion Resistance: It is less resistant to corrosion than some other types of steel, especially in wet or corrosive environments.

Properties of Ferrous Metals:

- Strength and Ductility: Ferrous metals, depending on their carbon content and other alloying elements, can range from very soft and ductile (such as pure iron) to hard and brittle (such as some cast irons).

- Machinability: The machinability of ferrous metals varies widely based on their composition. Pure iron and low-carbon steel are relatively easy to machine, while high-carbon and alloyed ferrous metals can be more challenging.

- Corrosion Resistance: Ferrous metals are generally less resistant to corrosion than non-ferrous metals like copper or aluminum. However, through alloying and surface treatments, their corrosion resistance can be improved.

High Carbon Steel vs Ferrous Metals – 3. Applications

Applications of High Carbon Steel:

- High carbon steel is commonly used in the manufacture of tools, knives, axes, and other cutting or abrasive implements due to its hardness and wear resistance.

- It is also used in the automotive industry for components that require high strength, such as springs and gears.

Applications of Ferrous Metals:

- Ferrous metals are ubiquitous in the construction, automotive, machinery, and many other industries due to their strength, ductility, and relatively low cost.

- Steel, a ferrous metal alloy with a controlled carbon content, is used in everything from skyscrapers to ships to surgical implants.

- Cast iron, another ferrous metal, is used in applications that require high compressive strength, such as machine bases and engine blocks.

Conclusion

In summary, high carbon steel and ferrous metals are distinct materials with different properties and applications. High carbon steel, with its high hardness and wear resistance, is ideal for cutting tools and abrasive applications, while ferrous metals, thanks to their strength and ductility, are ubiquitous in construction and heavy industries.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between High Carbon Steel vs Ferrous Metals. If you are looking for High Carbon Steel suppliers online now, please don’t hesitate to contact Huaxia Steel.

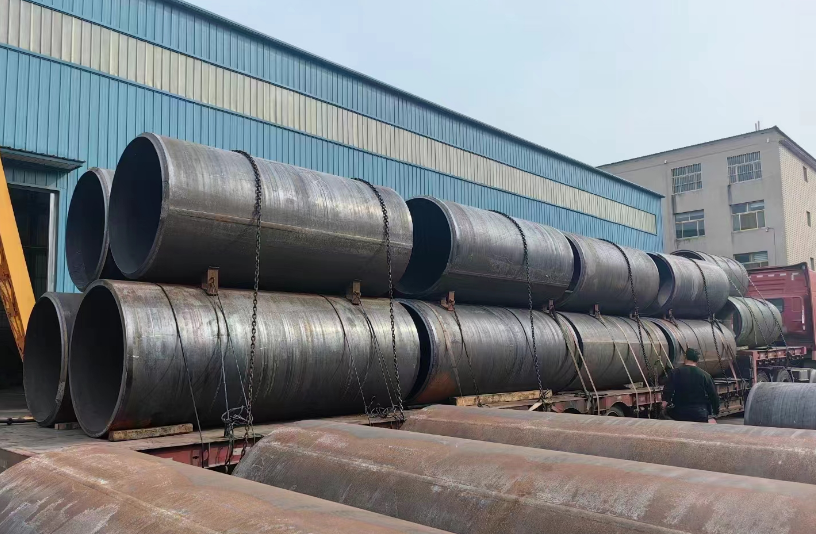

As a leading supplier of carbon steel products from Shanghai China, Huaxia Steel provides customers with high-quality carbon steel, tool steel, alloy steel, carbon steel tubes, and carbon steel pipes at a very competitive price.