In our daily life, we often use some steel materials in the building materials market. For people who have not been in the building materials market all year round, it is often difficult to accurately judge which building materials to use, and they spend a lot of money. Money, among which the choice of carbon steel is the representative. In this article, we will introduce how to determine which type of carbon steel to use.

How to determine which type of carbon steel to use?

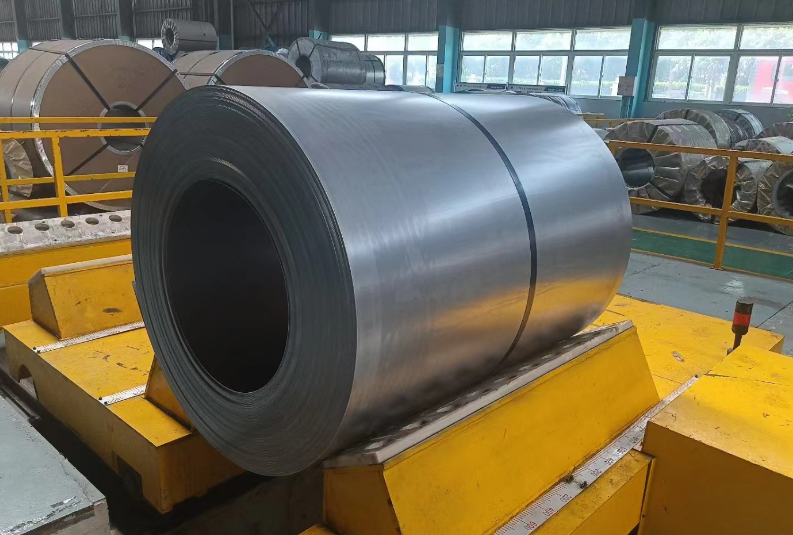

The reason why this happens is mainly due to the classification of carbon steel. Carbon steel is also called carbon steel. Generally, the carbon content is between 0.0218% and 2.11%. According to the different carbon content, it can be subdivided into low carbon steel. Carbon steel, medium carbon steel, high carbon steel; the complex classification method makes people difficult to choose.

In practical applications, low carbon steel has good ductility and toughness due to its carbon content of less than 0.25%, and is easy to process and form. It is often used to manufacture parts that require strength and toughness such as large structures and automobile bodies. The steel pipes, steel strips, steel plates, rivets, bolts, etc. that are often used in our building materials field also belong to the category of low carbon steel.

The carbon content of medium carbon steel is between 0.25% and 0.6%. Compared with low carbon steel, it has higher strength and hardness, slightly lower ductility, but has higher wear resistance. It is mainly used for high-strength mechanical parts. Manufacturing, such as bearings, gears, rollers, wheels, engines and other core components of large machinery.

High carbon steel has the characteristics of high hardness, high strength and low plasticity because its carbon content is greater than 0.60%. It is also called tool steel and is mainly used in the manufacture of cutting tools, such as drills, taps, reamers, etc. Parts with higher hardness requirements.

In addition, carbon steel, as an ideal material, also has good weldability and processability. Through welding, cold bending, heat treatment and other processes, it can meet the needs of parts and components in high-end manufacturing fields, such as Carbon steel is used in the fuselage, wings and other components of the domestic large aircraft C919.

Although carbon steel has many advantages, it also has obvious disadvantages. For example, SS400 is a widely used carbon steel material that is cheap, easy to process and weld, but is prone to rust. Therefore, everyone needs to do anti-rust treatment during use.

Conclusion

Thank you for reading our article and we hope it can help you to know how to determine which type of carbon steel to use well. If you are looking for carbon steel suppliers and manufacturers online now, we would advise you to visit Huaxia Steel.

As a leading supplier of carbon steel, Huaxia Steel offers customers high-quality carbon steel, tool steel and alloy steel products at a very competitive price.