Is carbon steel non stick?

Carbon steel is a popular material for cookware due to its durability and versatility. However, when it comes to non-stick cooking, not all materials are created equal. Let me tell you a story about a chef who was struggling to cook delicate foods like eggs and fish on their carbon steel pan. Despite their best efforts, the food always seemed to stick, leaving them with a messy and frustrating cleanup. That’s when they set out to understand whether carbon steel could be non-stick and how to achieve the perfect sear without sticking.

Carbon steel is not naturally non-stick, but it can become seasoned over time with repeated use and proper care. Seasoning involves coating the surface with a layer of oil and heating it to create a non-stick surface. However, this non-stick coating is not as durable as Teflon or ceramic coatings, and it requires regular maintenance to maintain its effectiveness.

In this article, we’ll explore this topic.

I. Introduction

Carbon steel is a popular material used in a variety of industries due to its durability, strength, and affordability. However, one question that often arises is whether carbon steel is non-stick or not. In this article, we will explore this question and discuss the use of non-stick coatings on carbon steel.

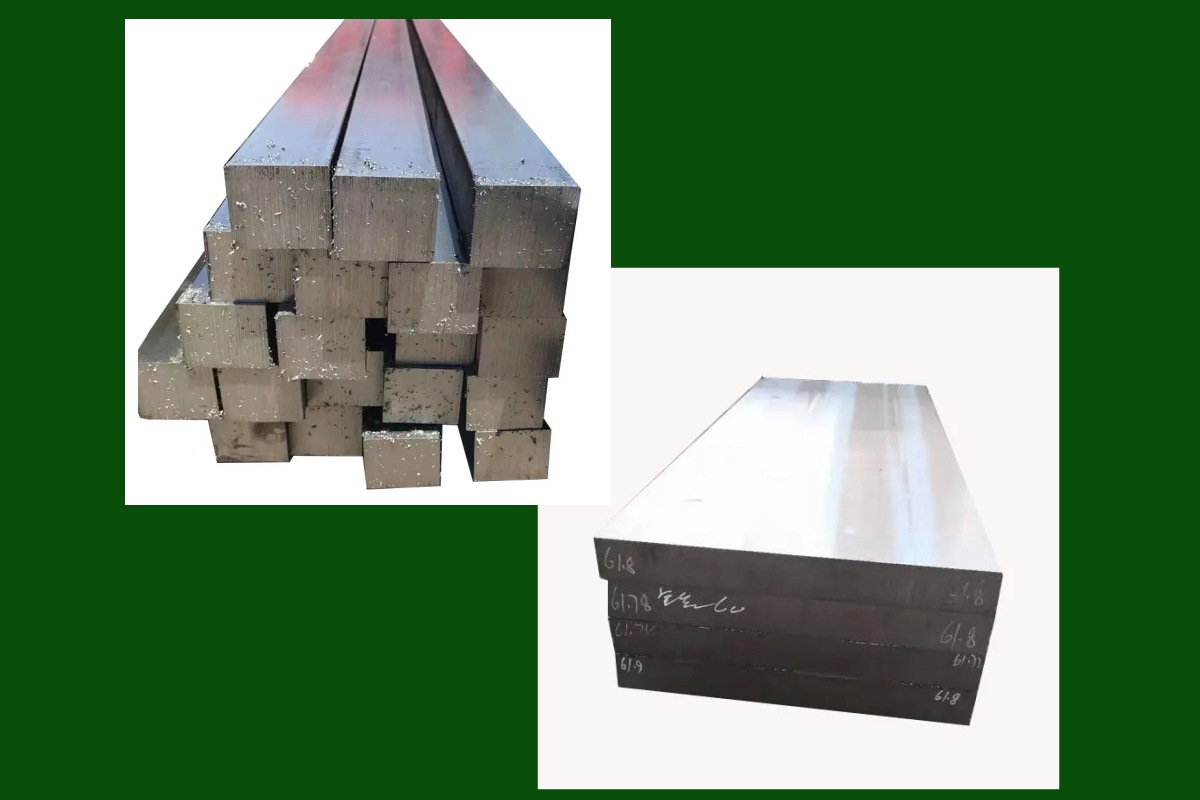

As carbon steel suppliers, it is important to understand the properties of the material we work with. Carbon steel is an alloy made up of iron and carbon, with varying amounts of other elements such as manganese, silicon, and copper. It is known for its strength and durability, making it a popular choice for construction and manufacturing industries. However, when it comes to cooking, many people prefer non-stick surfaces.

Non-stick coatings are applied to surfaces to prevent food from sticking and make cleaning easier. There are several types of non-stick coatings available, including ceramic, silicone, and Teflon. These coatings are often used on cookware such as frying pans and baking sheets.

The purpose of this article is to explore whether carbon steel is naturally non-stick or not and to discuss the use of non-stick coatings on carbon steel. In the following sections, we will delve deeper into these topics.

In the next section, we will provide an overview of carbon steel and its composition. We will also discuss how carbon steel differs from other materials in terms of stickiness. This will help us understand whether carbon steel is naturally non-stick or not.

Then, we will discuss non-stick coatings in detail. We will provide an overview of their properties and the common materials used for these coatings. We will also explain how non-stick coatings work and how they can be applied to carbon steel.

In the fourth section, we will answer the question of whether carbon steel is non-stick or not. We will compare carbon steel to other materials in terms of non-stick properties and discuss how non-stick coatings can be applied to carbon steel.

The fifth section will focus on the advantages and disadvantages of using non-stick carbon steel. We will compare non-stick carbon steel to other types of cookware and discuss the benefits and drawbacks of using it.

In the sixth section, we will provide tips for maintaining non-stick carbon steel. We will discuss best practices for cleaning and caring for this type of cookware.

In the conclusion, we will summarize the key points discussed in the article and provide final thoughts on whether carbon steel is non-stick or not. We will also provide recommendations for those considering using non-stick carbon steel.

II. Understanding Carbon Steel

Carbon steel is a popular material used in a wide range of applications due to its strength, durability, and versatility. It is made by combining iron and carbon, with carbon content ranging from 0.2% to 2.1%. Carbon steel is commonly used in construction, manufacturing, and transportation industries.

Carbon steel is known for its ability to conduct heat quickly and evenly, making it a popular choice for cookware. However, one common concern with using carbon steel cookware is its tendency to stick to food.

Here are some key points to understand about carbon steel:

Carbon steel has a high melting point and is resistant to deformation under pressure.

Carbon steel is classified into three main types: low carbon steel, medium carbon steel, and high carbon steel.

Carbon steel can be further divided into two categories: mild and hard steel.

Carbon steel suppliers provide a wide range of carbon steel products to meet different industrial and commercial needs.

Despite its popularity, carbon steel is not naturally non-stick. The degree of stickiness varies depending on the surface finish and how well the pan is seasoned.

Nonetheless, many manufacturers have developed non-stick coatings that can be applied to carbon steel cookware. These coatings provide a smooth, non-porous surface that prevents food from sticking to the pan. The most common non-stick coating used for carbon steel cookware is PTFE, also known as Teflon.

When looking for carbon steel cookware, it is important to consider the manufacturer’s reputation and the quality of the product. Reliable carbon steel suppliers can provide high-quality products that are safe, durable, and effective for cooking.

In the next section, we will explore non-stick coatings in more detail and how they work to prevent sticking.

III. Non-Stick Coatings

A. Overview of non-stick coatings and their properties

Non-stick coatings are a popular choice for cookware because they make cooking and cleaning easier. These coatings create a barrier between the cooking surface and the food being cooked, preventing the food from sticking to the surface. Non-stick coatings can be made from a variety of materials, including PTFE (polytetrafluoroethylene), ceramic, silicone, and enamel.

B. Common materials used for non-stick coatings

PTFE is the most common material used for non-stick coatings. This material is known for its durability, chemical resistance, and non-stick properties. Ceramic coatings are also becoming more popular because they are environmentally friendly and provide excellent non-stick performance. Silicone and enamel coatings are less common but can still be found on some cookware products.

C. Explanation of how non-stick coatings work

Non-stick coatings work by creating a layer of material between the cooking surface and the food being cooked. This layer prevents the food from sticking to the surface, making cooking and cleaning easier. The non-stick properties of the coating are achieved through the use of special materials that create a slippery surface. The coating is typically applied to the surface of the cookware through a process called spraying or dipping.

D. Importance of choosing a reputable supplier

When choosing cookware with non-stick coatings, it is important to choose a reputable supplier. This will ensure that the cookware has been manufactured to a high standard and that the non-stick coating is safe and durable. There are many carbon steel suppliers that offer cookware with non-stick coatings, but it is important to do research and choose a supplier with a good reputation in the industry.

E. Application of non-stick coatings to carbon steel

Carbon steel can be coated with non-stick materials to create non-stick cookware. The process of applying the coating involves cleaning and prepping the surface of the carbon steel, then spraying or dipping the surface with the non-stick material. The coated carbon steel is then cured in an oven to create a durable and long-lasting non-stick surface.

F. Advantages of using non-stick carbon steel

Non-stick carbon steel cookware offers many advantages, including easy cleaning, reduced use of oils and fats, and better food release. Non-stick coatings can also help to extend the life of carbon steel cookware by protecting it from rust and corrosion.

G. Disadvantages of using non-stick carbon steel

The main disadvantage of using non-stick carbon steel cookware is that the non-stick coating can wear off over time with regular use and cleaning. This can result in food sticking to the surface and reduced non-stick performance. Additionally, non-stick coatings can be damaged by high heat and metal utensils, so care must be taken when using and cleaning non-stick carbon steel cookware.

In summary, non-stick coatings are a popular choice for cookware, including carbon steel cookware. Choosing a reputable supplier is important to ensure that the non-stick coating is safe and durable. While non-stick carbon steel cookware offers many advantages, care must be taken to maintain the non-stick performance and prevent damage to the coating.

IV. Does Carbon Steel Have Non-Stick Properties?

A. Discussion of whether carbon steel is naturally non-stick

Carbon steel is a popular material used in cookware due to its durability, heat retention, and affordability. However, one question that many people have is whether or not carbon steel is naturally non-stick. The answer is no. Unlike some other materials like cast iron, carbon steel is not naturally non-stick.

B. Comparison of carbon steel to other materials in terms of non-stick properties

In terms of non-stick properties, carbon steel is not as good as materials like Teflon or ceramic, which have non-stick properties built into their surface. Carbon steel has a rougher surface, which can cause food to stick to it. However, with proper seasoning and use, carbon steel can develop some non-stick properties over time.

C. Explanation of how non-stick coatings can be applied to carbon steel

If you want to make your carbon steel cookware non-stick, you can apply a non-stick coating. These coatings can be applied to carbon steel through a variety of methods, including spraying, dipping, or electrostatic deposition. There are several types of non-stick coatings available, such as Teflon and ceramic coatings, which can be applied to carbon steel.

Carbon steel suppliers may also offer pre-coated carbon steel cookware, which comes with a non-stick coating already applied. This can be a convenient option for those who want non-stick carbon steel cookware without having to apply the coating themselves. However, it’s important to note that non-stick coatings can wear off over time with use and require proper care to maintain their non-stick properties.

D. Pros and cons of non-stick carbon steel

There are both advantages and disadvantages to using non-stick carbon steel cookware. The main advantage is that it combines the durability and heat retention of carbon steel with the non-stick properties of a coating. This makes it easier to cook delicate foods like fish or eggs without them sticking to the pan. However, the main disadvantage is that the non-stick coating can wear off over time, potentially exposing the underlying carbon steel to food and leading to sticking. Additionally, some people may have concerns about the safety of non-stick coatings and the potential release of harmful chemicals during cooking.

Overall, while carbon steel is not naturally non-stick, non-stick coatings can be applied to it to create a non-stick surface. Whether or not to use non-stick carbon steel cookware is a personal choice, and it’s important to weigh the pros and cons and properly maintain the cookware for optimal performance. Carbon steel suppliers may offer a variety of options, including pre-coated cookware, for those interested in non-stick carbon steel.

V. Advantages and Disadvantages of Non-Stick Carbon Steel

Non-stick carbon steel is a popular choice among home cooks and professional chefs alike. It offers several advantages over traditional carbon steel cookware, as well as some disadvantages to consider.

A. Advantages of Non-Stick Carbon Steel:

Non-stick surface: The non-stick coating on carbon steel makes it easy to cook delicate foods that might stick to traditional carbon steel. This is especially useful for foods like eggs or fish that require a gentle touch.

Lightweight: Carbon steel is naturally lightweight, making it easy to handle and maneuver in the kitchen. This is especially useful for larger pans and woks that might be too heavy if made from other materials.

Affordable: Carbon steel is relatively inexpensive compared to other types of cookware, making it an attractive option for those on a budget.

Durable: Carbon steel is known for its durability and can last for many years with proper care. The non-stick coating can also help protect the surface from scratches and other damage.

Versatile: Carbon steel can be used on all types of stovetops, including induction, and can also be used in the oven.

B. Disadvantages of Non-Stick Carbon Steel:

Non-stick coating can wear off: While the non-stick coating on carbon steel can last for a long time, it will eventually wear off with use. This can make the pan more difficult to clean and may require re-seasoning.

Limited heat resistance: Carbon steel is not as heat resistant as some other materials, such as cast iron, and can warp or even crack if exposed to high temperatures.

Not dishwasher safe: Carbon steel should not be washed in the dishwasher, as the harsh detergents and high heat can damage the non-stick coating and the surface of the pan.

Requires seasoning: While non-stick carbon steel is easier to clean than traditional carbon steel, it still requires seasoning to maintain its non-stick properties. This can be a time-consuming process for some cooks.

Not non-stick forever: Non-stick coatings, including those on carbon steel, are not designed to last forever. Over time, the coating will wear off and the pan may become less non-stick.

Overall, non-stick carbon steel is a great choice for those looking for a durable, affordable, and versatile cookware option. While it does have some disadvantages, the benefits of non-stick carbon steel make it a popular choice among both home cooks and professional chefs. When considering purchasing non-stick carbon steel, be sure to buy from reputable carbon steel suppliers and follow the manufacturer’s care instructions to ensure your cookware lasts for years to come.

VI. Maintaining Non-Stick Carbon Steel

Non-stick carbon steel cookware is a great investment for any kitchen. It is durable, versatile, and easy to use. However, to ensure that it lasts for a long time, proper maintenance is essential. Here are some tips for cleaning and caring for your non-stick carbon steel cookware:

A. Cleaning

One of the biggest advantages of non-stick carbon steel cookware is that it is easy to clean. After each use, you can simply wipe it down with a soft cloth or sponge. If you need to use soap, make sure to use a mild, non-abrasive soap and avoid using steel wool or abrasive pads, as they can scratch the non-stick coating. To remove stubborn stains, you can soak the cookware in warm water with a small amount of dish soap for a few minutes before wiping it down.

B. Storing

When storing your non-stick carbon steel cookware, make sure to stack it carefully to avoid scratching the non-stick coating. You can use felt or paper liners between the pots and pans to prevent scratches. It is also important to store the cookware in a dry, cool place to prevent rust.

C. Seasoning

Seasoning your non-stick carbon steel cookware regularly can help maintain its non-stick properties and extend its lifespan. To season your cookware, apply a thin layer of vegetable oil to the surface and heat it over medium-high heat for a few minutes. Allow the cookware to cool before wiping off any excess oil.

D. Best Practices

To ensure that your non-stick carbon steel cookware lasts for a long time, it is important to use it properly. Here are some best practices to follow:

- Always preheat the cookware before adding food.

- Avoid using metal utensils on the non-stick surface, as they can scratch the coating.

- Do not use high heat, as this can damage the non-stick coating and cause it to peel or flake.

- Use a lower heat setting and cook food for a longer time to prevent sticking.

- Avoid using abrasive cleaning tools and harsh chemicals, as they can damage the non-stick coating.

In conclusion, non-stick carbon steel cookware is a great option for any kitchen. It is versatile, durable, and easy to use. By following these tips for cleaning, caring, and seasoning your cookware, you can ensure that it lasts for a long time and retains its non-stick properties. Don’t forget to consult with carbon steel suppliers for additional advice on how to maintain and take care of your cookware.

VII. Conclusion

In conclusion, carbon steel is a popular material for cookware due to its durability, heat conductivity, and affordability. However, carbon steel is not naturally non-stick and can be prone to food sticking to the surface. To address this issue, non-stick coatings can be applied to carbon steel cookware.

Non-stick carbon steel cookware has many advantages, including easy food release and simple cleaning. However, there are also some disadvantages to using non-stick coatings, such as the potential for the coating to wear off over time.

When considering purchasing non-stick carbon steel cookware, it is important to research the different types of non-stick coatings and choose a reputable carbon steel supplier. There are many carbon steel suppliers on the market, and it is important to choose one that offers high-quality products and good customer service.

To maintain non-stick carbon steel cookware, it is important to follow proper cleaning and care instructions. This includes avoiding abrasive cleaners and utensils that can scratch the surface of the coating, and avoiding cooking at high temperatures.

In summary, while carbon steel is not naturally non-stick, non-stick coatings can be applied to make it an effective option for cookware. By choosing a reputable carbon steel supplier and following proper care instructions, non-stick carbon steel cookware can provide many benefits in the kitchen.

Related Blogs

Steel Pipe vs Steel Tube: Key Differences and Applications

Discover the key differences between steel pipes and steel tubes, including their uses, measurements, and schedules like schedule 40 vs schedule 80 pipes. Learn which is right for your project and how to choose the best steel solution.

General Materials of Honed Tubes

Honed tubes are typically made from materials such as carbon steel, alloy steel, stainless steel, and special alloys. Carbon steel, like ST52 and 45#, is widely used for its strength and affordability, making it ideal for hydraulic and pneumatic systems. Alloy steel, including grades like 16Mn and 27SiMn, offers enhanced wear resistance and strength for high-pressure applications. Stainless steel, such as 304 and 316, is favored for its corrosion resistance, especially in harsh environments. Special alloys like Inconel and Hastelloy are used in extreme conditions where high temperatures or corrosion resistance is essential, such as in marine and chemical industries.

The Relationship Between Carbon Steel and Tool Steel

Carbon steel and tool steel are two fundamental types of steel, each with its own specific properties and applications. While they share some similarities—both being forms of steel with varying carbon content—they serve very different purposes in industrial and manufacturing contexts. Understanding the relationship between carbon steel and tool steel can help clarify their unique roles and why each is chosen for specific applications.

Table of Contents

Request A Free Quote

We’d like to work with you

By Huaxia-steel – Alloy Steel Suppliers

If you require further information about our metal sheet products or architectural projects, please don’t hesitate to leave your contact details and message here.

Our team of experts will respond within 24 hours to continue the discussion and provide you with any additional information you requires.