Alloy steel, as a widely used metallic material, boasts exceptional properties that have made it indispensable in industries such as automotive manufacturing, petrochemicals, and aerospace. To ensure that alloy steel possesses superior performance and quality, rigorous control over every step of the manufacturing process is essential. In this article, we’ll take a closer look at the processing and manufacturing process of alloy steel.

Processing and Manufacturing Process of Alloy Steel:

Firstly, in terms of material selection, alloy steel comprises various alloying elements, including chromium, molybdenum, vanadium, titanium, and nickel, which impart unique properties to the steel. For instance, carbon enhances strength and hardness, while nickel and chromium bolster corrosion resistance and high-temperature performance. As different alloying elements confer distinct properties to alloy steel, the choice of materials must be tailored to the specific application areas, working environments, and other factors.

Secondly, alloy steel melting involves combining the selected raw materials in precise proportions and heating them to a molten state. Careful temperature control during melting ensures optimal mixing and composition. Additionally, introducing appropriate ratios of gases and chemicals during the melting process helps eliminate waste gases and impurities, thereby enhancing alloy performance and quality.

Furthermore, casting is a crucial step in the alloy steel processing and manufacturing process. It involves pouring qualified molten steel into molds to form ingots or billets of desired shapes, sizes, and weights suitable for subsequent rolling or forging operations. There are two primary casting methods: continuous casting and discrete casting. Continuous casting utilizes a cavity-type casting machine to produce continuous steel billets directly, while discrete casting involves pouring molten steel into molds, allowing it to solidify, cool, and be ejected as steel ingots.

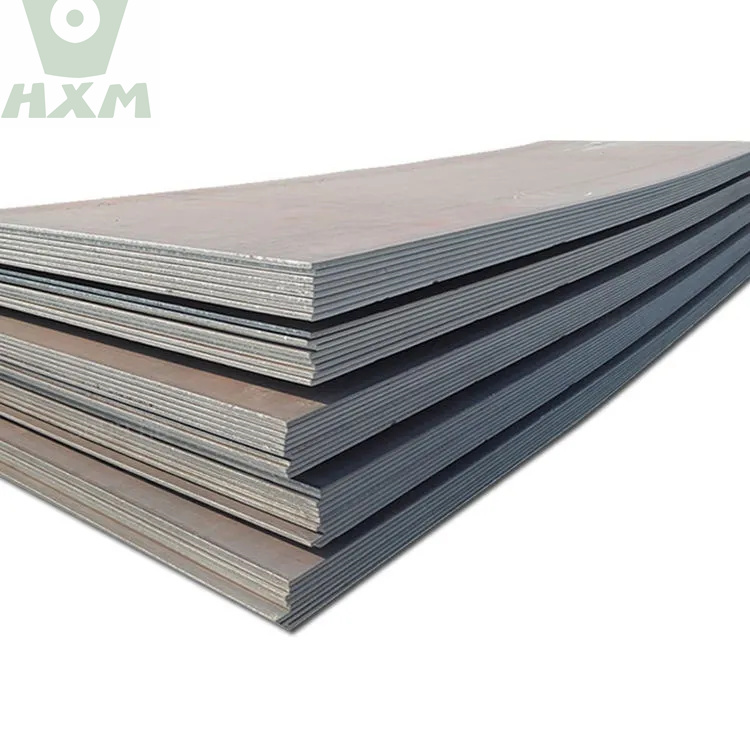

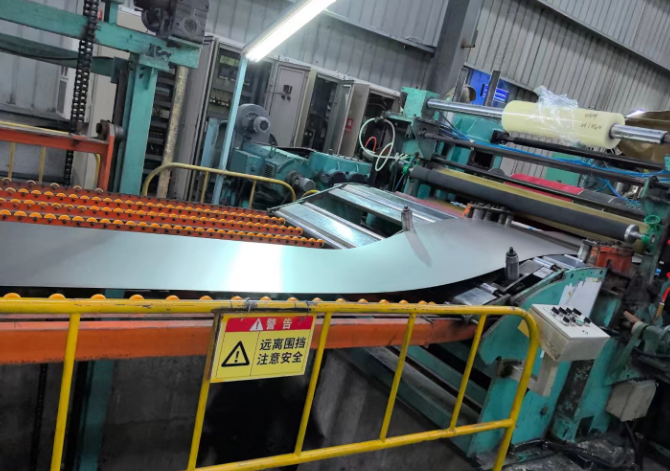

In addition, rolling is a vital metalworking process applied to alloy steel. After casting, the billets undergo rolling, which compresses the metal to reduce its cross-section and increase its length, thereby altering its shape and dimensions. Two common rolling methods are hot rolling and cold rolling. Hot rolling improves the material’s microstructural properties, enhancing steel’s strength and toughness. In contrast, cold rolling involves controlling the pressure and temperature during the rolling process to refine the metal’s microstructure, focusing on factors such as alloy steel’s dimensions and surface quality.

Finally, quenching, a common heat treatment process, plays a significant role in alloy steel processing. The objective of quenching is to transform supercooled austenite into martensite or bainite, resulting in a microstructure composed of these phases. Various quenching methods include water quenching, oil quenching, gas quenching, and salt quenching. This process enhances alloy steel’s rigidity, wear resistance, fatigue strength, and toughness, meeting the demanding requirements of various mechanical parts and tools.

Summary

In summary, the production of alloy steel is a complex and intricate process. To ensure optimal quality and performance, every step, from raw material selection and melting, through casting and rolling of steel billets, to quenching, must be meticulously controlled. Only by doing so can we guarantee the production of high-quality alloy steel products.

Why Choose Huaxia Steel?

Thank you for reading our article and we hope it can help you to have a better understanding of the processing and manufacturing process of alloy steel. If you are looking for alloy steel suppliers and manufacturers online now, we would advise you to visit Huaxia Steel.

As a leading supplier of alloy steel from Shanghai China, Huaxia Steel offers customers high-quality alloy steel, tool steel, and carbon steel at a very competitive price.