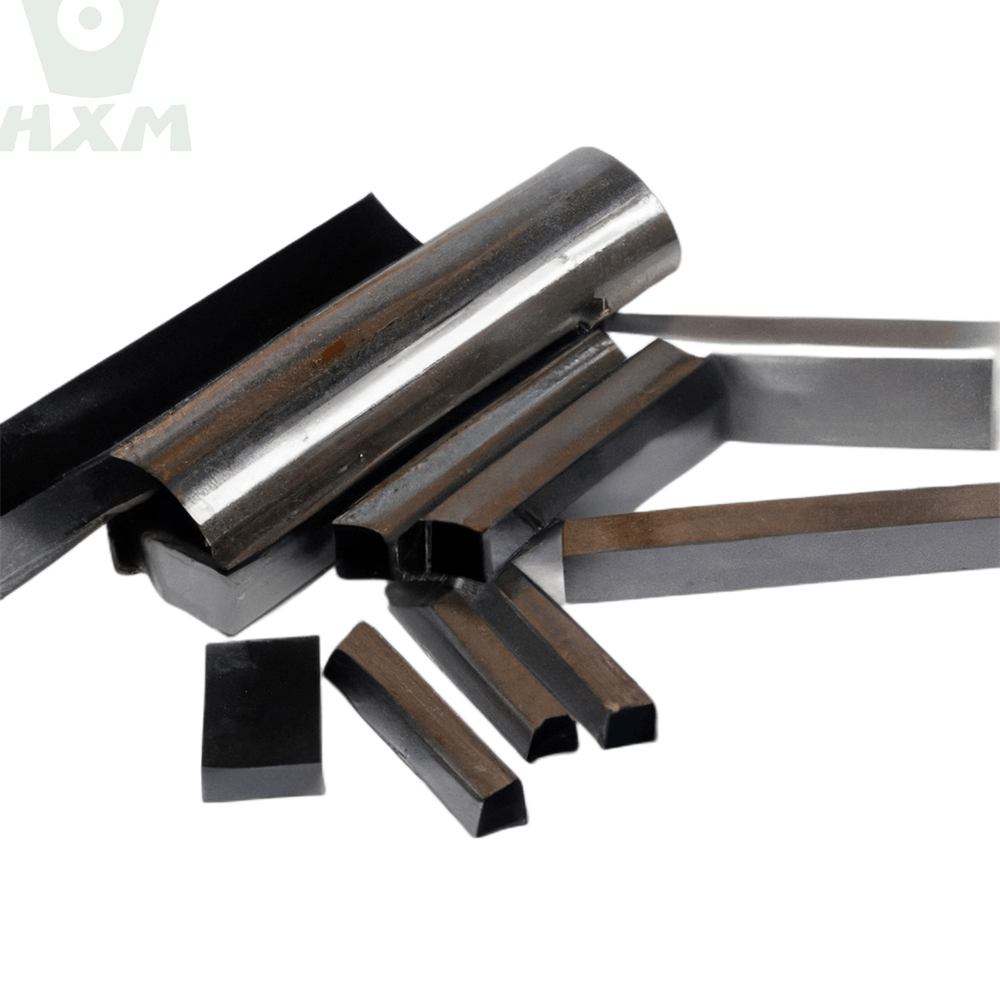

As a high-performance steel type, alloy tool steel is widely utilized in the manufacturing of mechanical components such as molds, cutting tools, and bearings due to its remarkable properties like high hardness, toughness, wear resistance, and corrosion resistance. However, despite its exceptional strength, alloy tool steel is susceptible to rusting when exposed to humid, acidic, or alkaline environments over an extended period. Consequently, it is imperative to implement appropriate rust prevention measures during the application of alloy tool steel. In this article, we will take a closer look at the rust prevention measures for alloy tool steel.

Rust Prevention Measures for Alloy Tool Steel:

Firstly, in terms of surface treatment. Subjecting alloy tool steel to surface treatments such as phosphating, cleaning, polishing, and oxidation can significantly enhance its rust resistance. For instance, phosphating involves forming a phosphate conversion coating, known as a phosphate film, on the surface of alloy tool steel. This protective layer effectively impedes the oxidation reaction between the external oxygen and the internal metal, thereby preventing rust.

Secondly, coating treatment is another effective method. Applying a non-toxic and environmentally friendly rust-proof coating onto the surface of alloy tool steel creates a barrier against water and air, preventing chemical reactions that would otherwise accelerate oxidation. Additionally, coating treatment not only prevents rust but also enhances the steel’s wear and corrosion resistance, broadening its application in various fields.

Furthermore, plating treatment plays a crucial role in rust prevention. By plating alloy tool steel, a protective film is formed on its surface, effectively isolating it from oxygen, water, and other corrosive agents. This reduces or eliminates the occurrence of rust. Chromium plating, for example, utilizes chromium’s ability to form a dense oxide layer upon reaction with oxygen, which seals off the surface from the environment, contributing to rust prevention. Moreover, chromium plating enhances the aesthetic appeal of alloy tool steel while providing robust rust protection.

Lastly, packaging protection is essential during storage and transportation. Alloy tool steel often comes into contact with air and water during these processes, leading to rusting and potentially compromising its mechanical properties. Employing rust-preventive oil packaging or vapor-phase rust-preventive packaging techniques can isolate the metal surface from oxygen and water vapor, effectively preventing rust and preserving the quality and performance of alloy tool steel.

Conclusion

In conclusion, while alloy tool steel is a high-performance alloy material, it is still prone to rusting during application. However, through measures such as surface treatment, coating treatment, plating treatment, and packaging protection, we can effectively prevent rust, thereby extending the service life of alloy tool steel.

Why Choose Huaxia Steel?

Thank you for reading our article and we hope it can help you to have a better understanding of the rust prevention measures for alloy tool steel. If you are looking for suppliers and manufacturers of alloy tool steel, we would advise you to visit Huaxia Steel.

As a leading supplier of alloy tool steel, Huaxia Steel offers customers high-quality carbon steel, tool steel, and alloy steel at very competitive prices.