In industrial production, to ensure the final product quality and meet actual application requirements, it is usually necessary to perform necessary surface treatments on carbon steel. These treatment methods play a crucial role in improving the performance and applicability of carbon steel. The commonly used surface treatment methods of carbon steel mainly include the following:

Surface Treatment Methods of Carbon Steel:

Firstly, ultrasonic shot peening, which involves bombarding carbon steel workpieces with shot peening of varying diameters. This method not only improves the surface hardness and wear resistance of carbon steel but also effectively extends the service life of carbon steel workpieces.

Secondly, chemical degreasing, which is carried out after shot peening to ensure specific surface characteristics for subsequent processing or different application requirements. Under controlled temperature conditions, chemical degreasing agents are applied to the carbon steel surface, ensuring it is prepared for further treatment.

Thirdly, blackening treatment, essential for preventing corrosion when carbon steel is exposed to moist or chemically corrosive environments. This involves acid pickling the carbon steel workpiece followed by blackening at high temperatures, forming a protective layer that enhances corrosion resistance.

Fourthly, grinding and polishing, which significantly improves the appearance of carbon steel by achieving a smooth, shiny, or textured surface as required. This process enhances both the practicality and aesthetics of carbon steel.

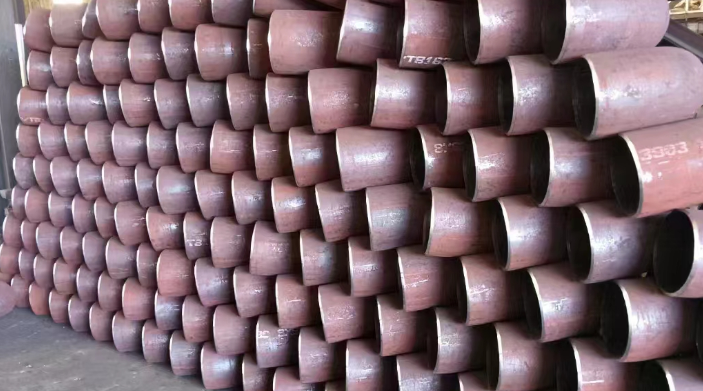

Fifthly, combined treatment methods, addressing the formation of oxide scale during hot rolling or cooling of carbon steel, as well as potential rusting during storage and transportation. Mechanical-chemical combined processes effectively remove oxide scale and rust, restoring the original properties of carbon steel, particularly for hot-rolled coils and other workpieces.

Sixthly, EPS treatment, an environmentally friendly descaling technique that utilizes a mixture of steel grit and water sprayed onto the steel surface through nozzles, creating a smooth and clean surface. Performing EPS treatment on carbon steel prior to machining enhances processing quality and efficiency.

Seventhly, painting and coating, which involves high-pressure cleaning with anti-corrosion solutions containing rust inhibitors after shot peening and drying. Subsequently, applying necessary coatings to the carbon steel surface not only improves the adhesion of the coating but also ensures stable carbon steel performance.

Summary

In summary, surface treatments for carbon steel not only enhance its wear and corrosion resistance but also improve its appearance and aesthetics. Furthermore, proper surface treatments can increase the fatigue strength of carbon steel, reduce performance degradation caused by cyclic loading, and ultimately enhance its market competitiveness.

Why Choose Huaxia Steel?

Thank you for reading our article and we hope it can help you to have a better understanding of the surface treatment methods of carbon steel. If you are looking for carbon steel suppliers and manufacturers online now, we would advise you to visit Huaxia Steel for more information.

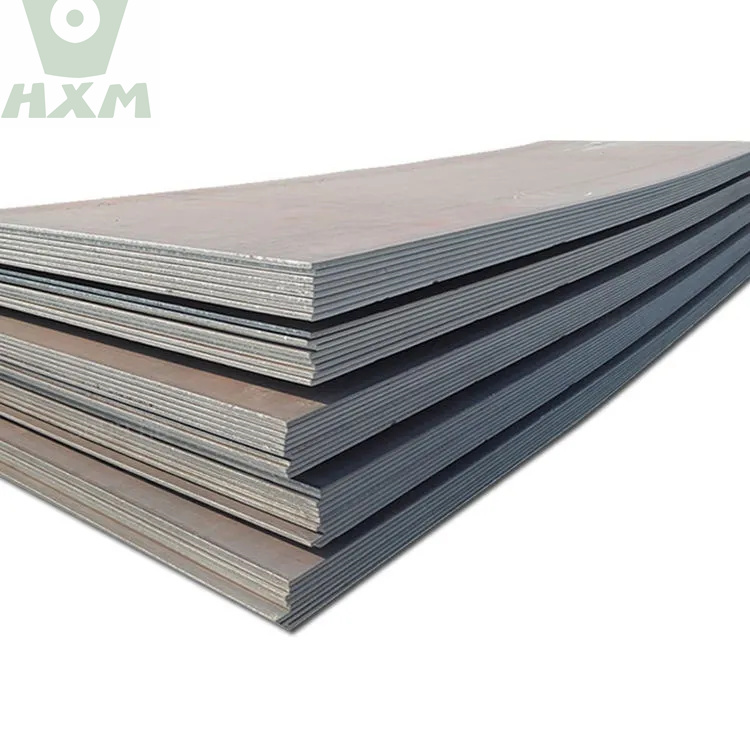

As a leading supplier of carbon steel from Shanghai China, Huaxia Steel offers customers high-quality carbon steel products such as LOW -CARBON STEEL, MEDIUM CARBON STEEL and HIGH CARBON STEEL at a very competitive price.