In the vast world of metallurgy, steel stands as a cornerstone, its diverse types and applications shaping numerous industries. Among the various types of steel, tool steel and carbon steel occupy prominent positions, each with its unique properties and usages. This article aims to delve into the intricate differences between these two types of steel.

What is the difference between tool steel and carbon steel?

Let’s begin with a fundamental understanding of carbon steel. Carbon steel is an alloy of iron and carbon, with carbon content ranging typically from 0.2% to 2.1% by weight. This carbon content significantly influences the steel’s mechanical properties, such as hardness, tensile strength, and ductility. Carbon steel is further classified into three main categories: low-carbon steel, medium-carbon steel, and high-carbon steel. Low-carbon steel is known for its good weldability and ductility, making it suitable for applications that require bending or shaping. On the other hand, high-carbon steel, with its increased carbon content, exhibits higher hardness and wear resistance, but at a cost of reduced ductility.

Now, let’s turn our attention to tool steel. Tool steel is a subset of carbon steel, specifically designed for the manufacture of cutting and shaping tools due to its exceptional hardness, wear resistance, and heat resistance. It contains additional alloying elements, such as chromium, molybdenum, tungsten, and vanadium, which further enhance its mechanical properties. Tool steel is typically divided into five main types: water-hardening, oil-hardening, air-hardening, high-speed, and molybdenum high-speed steel. Each type is optimized for specific applications and working conditions. For instance, water-hardening steel is suitable for tools that require quick hardening but are not exposed to extreme temperatures, while high-speed steel is ideal for cutting tools that need to withstand high temperatures generated during machining operations.

The primary difference between tool steel and carbon steel lies in their intended uses and the alloying elements they contain. Carbon steel, with its varying carbon content, is a general-purpose material used in a wide range of applications, from construction to automotive parts. Its properties can be tailored to suit different needs through heat treatment and alloying. On the other hand, tool steel is specifically designed for the most demanding tool-making applications, where extreme hardness, wear resistance, and heat resistance are paramount. The addition of alloying elements in tool steel not only enhances these properties but also allows for finer control over the steel’s microstructure and performance.

Moreover, the manufacturing processes for these two types of steel also differ. Carbon steel is typically produced through basic steel-making processes, such as blast furnace smelting and rolling. Tool steel, on the other hand, often requires more specialized production methods, including vacuum degassing, powder metallurgy, and precision heat treatment, to ensure the homogeneity and consistency of its alloy composition and microstructure.

In terms of cost, tool steel generally commands a higher price due to its specialized nature and the added complexity of its production process. Carbon steel, being more widely used and produced in larger quantities, is typically more economical.

It’s worth noting that while tool steel excels in hardness and wear resistance, it may not be suitable for all applications. Its brittleness and reduced ductility compared to some carbon steel grades can limit its use in certain scenarios where flexibility or toughness is crucial.

Conclusion

In conclusion, the difference between tool steel and carbon steel lies in their composition, intended uses, manufacturing processes, and associated costs. Carbon steel is a versatile material suitable for a wide range of applications, while tool steel is a specialized alloy optimized for the most demanding tool-making tasks.

Thank you for reading our article and we hope it can help you to have a better understanding of the differences between tool steel and carbon steel. If you are looking for tool steel and carbon steel suppliers and manufacturers online now, we would advise you to visit Huaxia Steel.

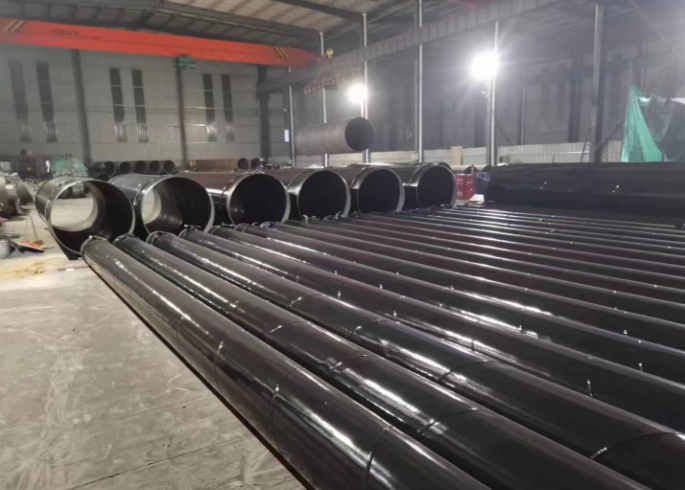

As a leading supplier of carbon steel and tool steel from Shanghai China, Huaxia Steel offers customers high-quality As a leading supplier of carbon steel products from Shanghai China, Huaxia Steel offers customers high-quality carbon steel, tool steel, alloy steel, and carbon steel tubes at a very competitive price.