AISI 1045 Steel/C45 Steel

Product Name: Carbon Steel 1045/C45

Material: 1045/C45

Category: Medium carbon steel

Supply steel mills:

Baosteel, Anshan Iron and Steel, Meishan Iron and Steel

Storage place: Shanghai

Processing available:

Kaiping, slitting, cold rolling, quenching and tempering

Huaxia is a professional C45 steel /AISI 1045 steel supplier.

Our Advantages:

1. More than ten years of export experience

2. Rich products

(carbon steel, stainless steel, aluminum)

3. Timely response within 12 hours

Welcome to send us inquiries directly

Details for 1045/C45 Steel:

Is AISI 1045 mild steel?

No, 1045/C45 steel is a medium carbon structural steel with good cold and hot workability, good mechanical properties, low price, and wide sources, so it is widely used. Its biggest weakness is that workpieces with low hardenability, large section size, and high requirements should not be used.

The quenching temperature of 1045/C45 steel is A3+(30~50) ℃. In actual operation, the upper limit is generally taken. Higher quenching temperatures can speed up workpiece heating, reduce surface oxidation, and improve work efficiency.

To homogenize the austenite of the workpiece, the sufficient holding time is required. If the actual charging amount is large, it is necessary to extend the holding time appropriately.

Otherwise, insufficient hardness may occur due to uneven heating. However, if the holding time is too long, the defects of coarse grains and oxidation decarburization will also occur, which will affect the quenching quality.

We believe that if the furnace loading is greater than the provisions of the process document, the heating and insulation time should be extended by 1/5.

Because the hardenability of 1045/C45 steel is low, a 10% brine solution with a high cooling rate should be used. After the workpiece is filled with water, it should be quenched, but not cooled. If the workpiece is cooled in brine, it may crack.

This is because when the workpiece is cooled to about 180 ℃, the austenite rapidly transforms into martensite, causing excessive structural stress. Therefore, when the quenched workpiece is rapidly cooled to this temperature zone, the slow cooling method should be adopted.

As the outlet water temperature is difficult to master, it must be operated by experience. When the workpiece in the water stops shaking, the outlet water can be cooled by air (oil cooling is better).

In addition, the workpiece should be dynamic rather than static when entering the water. It should move regularly according to the geometric shape of the workpiece. The static cooling medium plus the static workpiece will lead to uneven hardness and stress, leading to large deformation and even cracking of the workpiece.

The hardness of quenched and tempered parts of 1045/C45 steel should reach HRC56~59, which may be lower if the section is large, but not lower than HRC48. Otherwise, it means that the workpiece has not been completely quenched, and sorbate or even ferrite structure may appear in the structure. This structure is still retained in the matrix through tempering, which cannot achieve the purpose of quenching and tempering.

For high-temperature tempering of 1045/C45 steel after quenching, the heating temperature is usually 560~600 ℃, and the hardness is required to be HRC22~34. Because the purpose of quenching and tempering is to obtain comprehensive mechanical properties, the hardness range is relatively wide.

However, if the drawing has hardness requirements, the tempering temperature shall be adjusted according to the drawing requirements to ensure the hardness. If some shaft parts require high strength, the hardness is required to be high; However, some gears and shaft parts with keyways need to be milled and inserted after quenching and tempering, so the hardness requirements are lower.

As for the tempering and heat preservation time, it depends on the hardness requirements and the size of the workpiece. We believe that the hardness after tempering depends on the tempering temperature and has little to do with the tempering time, but it must be back penetrated. Generally, the tempering and heat preservation time of the workpiece is more than one hour.

Physical Properties of AISI 1045

What is 1045 steel used for?

1045/C45 steel is widely used in machinery. When it is not heat treated, HB ≤ 229; Heat treatment: normalizing; Impact energy: Aku ≥ 39J; It has high strength, good plasticity, and toughness.

1045/C45 steel plate is qualified if its hardness is greater than HRC55 (up to HRC62) after quenching and before tempering. After heat treatment, it can reach HRC42-46 after tempering, which can not only ensure its good mechanical properties but also obtain the surface hardness requirements.

It is used to make small sections of quenched and tempered parts with large loads and large normalized parts with small stress, As well as the surface hardened parts with low requirements on the central strength, such as pins, guide pillars, watch needles, and other components.

Welding AISI 1045 steel

1045 steel is suitable for hydrogen welding and argon arc welding, but not suitable for gas welding. Preheating is required before welding, and stress relief annealing shall be carried out after welding.

Standard – AISI 1045 Steel/C45 Steel:

Chemical Requirements

component | C | Si | Mn | P | S | Cu | Ni | Cr |

minimum value | 0.42 | 0.17 | 0.5 | – | – | – | – | – |

maximum value | 0.5 | 0.37 | 0.8 | 0.035 | 0.035 | 0.25 | 0.3 | 0.2 |

Mechanical Properties‘ Requirements

category | yield strength | tensile strength | Elongation | Reduction of area | hardness | Decarburized layer |

Rm | Rm | % | % | Hot Rolled | both sides | |

(Mpa) | (Mpa) | |||||

minimum value | 355 | 600 | 16 | |||

maximum value | 229HB | |||||

Number |

AISI 1045 Steel/C45 Steel Available:

Hot Rolled Stock Specifications

Thickness:

2.0mm~8.0mm

Width:

15mm~620mm, 1000mm~1250mm, or 2000mm~2200mm

Hardness:

The factory hot rolling hardness of the steel plant is about hrb85 degrees, and the slightly hard steel is about hrb90 degrees. Normally, it can be directly cut.

After general heat treatment, the quenching and tempering target hardness of AISI 1045 steel is in the range of hrc37~hrc42, depending on the heat treatment process and product requirements.

Heat treatment specification:

Normalized, 850 ℃; Quenching, 840 ℃; Tempering, 600 ℃

Metallographic structure:

Delivery state:

Comparison table of different standards for AISI 1045/C45 steel:

Chinese | Germany | France | International standard | Japan | Sweden | England | America | ||

GB | NF | JIS | SS | BS | |||||

DIN | W-Nr. | ISO | ASTM | UNS | |||||

45# | C45E | 1.1191 | C45E | C45E4 | S45C | 1660 | C40E | G10450 | |

Applications of 1045/C45 Steel:

The carbon content of 1045/C45 steel is in the range of 0.42%~0.50%, which is equivalent to the Japanese standard s45c. 1045/C45 steel is widely used in machinery, mainly for the production of small-section quenched and tempered parts with large loads and large normalized parts with low stress, as well as surface quenched parts that do not require high core strength, such as tips and guide posts. , hands and other components.

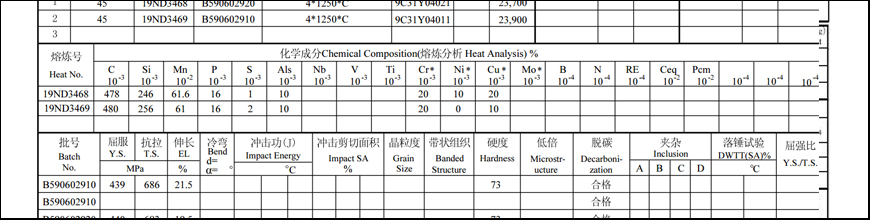

(Quality Certificate of AISI 1045/C45 Steel)

What are the differences in properties between 1045/C45 Steel and AISI 1035 Steel?

1045/C45 steel is a high-quality carbon structural steel, commonly known as high-quality steel, which belongs to medium carbon structural steel. This type of steel does not intentionally add alloy elements to the steel but is also a widely used high-quality structural steel. The use of 1045/C45 steel depends on its various properties.

1045/C45 steel has a certain degree of toughness and plasticity, high strength, good processability, and good comprehensive mechanical properties that can be obtained by quenching and tempering.

1045/C45 steel is suitable for manufacturing high-strength moving parts, such as air compressors, pump pistons, steam turbine impellers, rolling shaft, connecting rod, worm, rack, gears, pin, etc. in heavy and general machinery.

1045/C45 steel is usually used in the quenched and tempered or normalized state, which can replace the carburized steel and is used to manufacture surface wear-resistant parts.

At this time, it must be subject to high-frequency induction or flame quenching, such as crankshaft, gear, machine tool spindle, piston pin, transmission shaft, etc. It is also used to manufacture medium load shafts, threshing drums, concave nail teeth, sprockets, gears, bench tools, etc. of agricultural machinery.

1025 is a medium carbon quenched and tempered steel with higher strength, toughness, and hardenability than 45 steel. The quenching and tempering treatment can obtain better comprehensive mechanical properties, and good machinability, but poor weldability.

It is generally used for parts under heavy load and wear-resistant working conditions, such as crankshaft, spline shaft, shaft, connecting rod, Cardan shaft, automobile half shaft, gear, clutch plate, bolts, nuts, etc.

1045/C45 steel is usually used in the quenched and tempered or normalized state, which can replace the carburized steel and is used to manufacture surface wear-resistant parts.

At this time, it must be subject to high-frequency induction or flame quenching, such as crankshaft, gear, machine tool spindle, piston pin, transmission shaft, etc. It is also used to manufacture medium load shafts, threshing drums, concave nail teeth, sprockets, gears, bench tools, etc. of agricultural machinery.

Can 1045/C45 steel replace AISI 1035 Steel?

If there are no requirements for strength, hardness, and other conditions, it doesn’t matter. But if you want high strength, hardness, and modulus, you can’t. Because 1045/C45 steel is only ordinary carbon steel, its strength and hardness have increased significantly after adding Mn. It applies to machines with high strength requirements.