AISI 1020 Steel/S20C Steel

Product Name:

AISI 1020 Steel/S20C Steel

Material:

AISI 1020 Steel/S20C Steel

Category:

low carbon steel

Processing available:

Kaiping, slitting, cold rolling, quenching and tempering

Huaxia is a professional AISI 1020 Steel/S20C supplier.

Our Advantages:

1. More than ten years of export experience

2. Rich products (carbon steel, stainless steel, aluminum)

3. Timely response within 12 hours Welcome to send us inquiries directly.

Characteristic for 1020 Steel /S20C:

1020 steel/S20C steel belongs to high-quality low-carbon carbon steel, cold extrusion, carburizing and hardening steel. It has low strength, good toughness, plasticity and weldability. The tensile strength is 253-500MPa, and the elongation is ≥ 24%. The properties of 1020/S20C steel are basically similar to that of C15 steel, but the strength is slightly higher. It is suitable for manufacturing small and medium-sized carburized carbonitriding and other parts that are not very important in automobile, tractor and general machinery manufacturing, such as hand brake shoe, lever shaft, gearbox speed fork, transmission passive gear, camshaft on tractor, suspension balancer shaft, inner and outer bushing of balancer, etc; In the hot rolling or normalizing state, it is used to manufacture various mechanical parts with low stress and high toughness; In heavy and medium machinery manufacturing industry, such as forged or pressed pull rod, shackle, lever, sleeve, fixture, etc. In the steam turbine and boiler manufacturing industry, it is mainly used for pipes, flanges, headers and various fasteners working in non corrosive medium with pressure ≤ 6N/m2 and temperature ≤ 450 ℃; It is used for manufacturing crosshead, piston and other castings on railway and rolling stock. Normalizing can promote the spheroidization of the steel, refine the massive proeutectoid ferrite, and improve the cutting performance of blanks less than 160HBS. The process route of the steel die parts is: blanking → forging die blank → annealing → rough machining → cold extrusion molding → recrystallization annealing → mechanical finishing → carburizing → quenching and tempering → grinding and polishing → assembly.

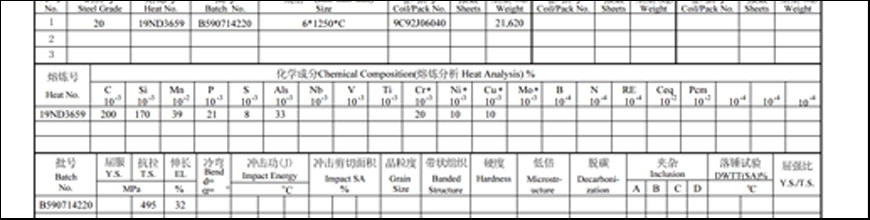

Chemical composition of AISI 1020 Steel/S20C Steel

component | C | Si | Mn | P | S | Cu | Ni | Cr |

minimum value | 0.07 | 0.17 | 0.35 | – | – | – | – | – |

maximum value | 0.23 | 0.37 | 0.65 | 0.035 | 0.03 | 0.25 | 0.3 | 0.2 |

Mechanical Properties of AISI 1020 Steel/S20C Steel

category | yield strength | tensile strength | Elongation | Reduction of area | hardness | Decarburized layer |

Rm | Rm | % | % | Hot Rolled | both sides | |

(Mpa) | (Mpa) | |||||

minimum value | 245 | 410 | 28 | |||

maximum value | ||||||

Number |

AISI 1020 Steel/S20C Steel Available:

Cold Rolled Stock Specifications

Thickness: 2.0mm~9.0mm

Width: 15mm~620mm, 1,000mm~1,250mm or 2,000mm~2,200mm

Hardness: No heat treatment ≤ 197HB

Surface: blue, black, polished, bright, mirror

Hot Rolled Stock Specifications

Thickness: 2.0mm~70.0mm

Width: 15mm~620mm, 1,000mm~1,250mm or 2,000mm~2,200mm

Hardness: No heat treatment ≤ 197HB

Applications:

1020/S20C low carbon steel belongs to high-quality low carbon steel, which is cold extruded and hardened. The steel has low strength, good toughness, plasticity and weldability. Many customers need S15C steel. In fact, the overall performance of S15C steel is not much different from that of 1020/S20C steel. If there is a suitable 1020/S20C steel with lower carbon content, it may be confirmed by production technicians that the sample can be basically equivalent if it is acceptable. 1020/S20C steel is suitable for manufacturing small and medium-sized carburized (or carbonitrided) parts that are not very important in automobile, tractor and general machinery manufacturing, such as hand brake shoe, lever shaft, gearbox speed fork, transmission passive gear, camshaft on tractor, suspension balancer shaft, inner and outer bushing of balancer, etc.

(Quality Certificate of 1020/C20/S20C)

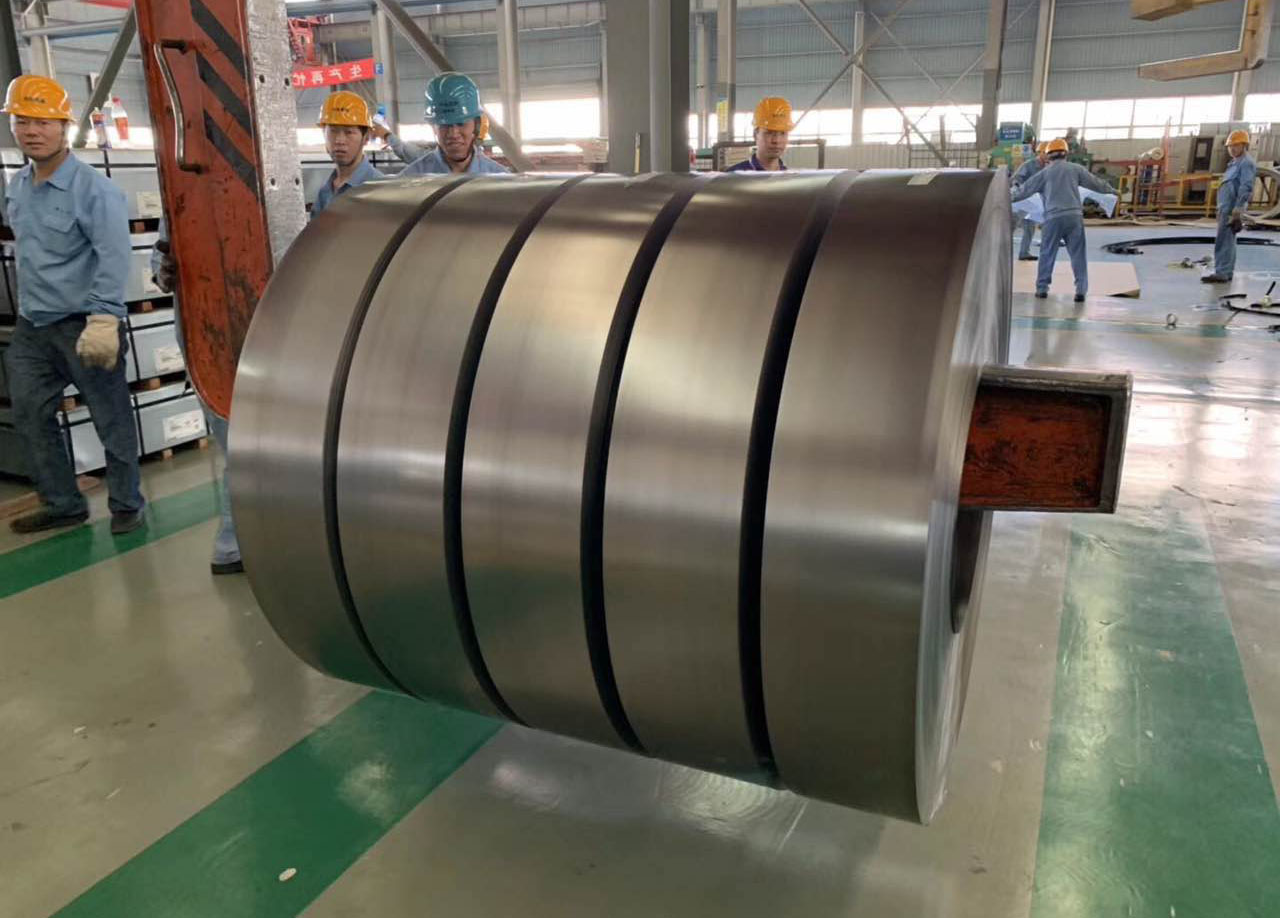

Product Display:

The differences between 1020/C20/S20C & 1035/C35/S35C:

1020/C20/S20C and 1035/C35/S35C belong to high-quality carbon steel, and their carbon content is different. The carbon content of 1020/C20/S20C is about 0.2%; The carbon content of 1035/C35/S35C is about 0.35%. The main differences are as follows: 1020/C20/S20C belongs to low carbon steel with good plasticity, which is mainly used to make sections that can be punched, such as steel pipes and plates; 1035/C35/S35C is medium carbon steel with high strength. It is mainly used to make mechanical parts requiring heat treatment, such as gears, shafts, etc. To distinguish the two, use the grinding wheel to spark. The one with the big spark is 1035/C35/S35C.