The 1035 steel(S35C) is made of carbon structural steel, which performs well in plasticity, strength and process performance. It has certain weldability and can be welded in the normalized state. 35 # steel is the raw material for many forgings, hot-pressed parts and cold-drawn parts. It has a wide range of uses. It can be used to make seamless steel pipes, crankshaft, shaft pins and other parts, as well as beams, screws, nuts and so on.

1035 steel, also known as S35C, is a medium-carbon steel used in the manufacture of various components, including shafts, gears, pins, and more. The following are some of the key characteristics of 1035 steel:

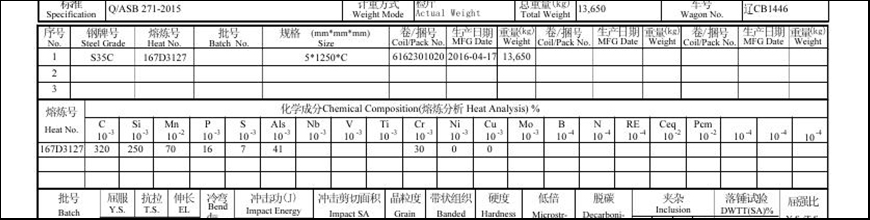

1. Composition: 1035 steel consists of carbon (0.32-0.38%), manganese (0.60-0.90%), phosphorus (0.040%) and sulfur (0.050%) as the main alloying elements.

2. Hardness: 1035 steel can be heat treated to increase its hardness, but in its as-rolled condition, it has a Brinell hardness of approximately 120-160.

3. Strength: 1035 steel has good strength and toughness, making it suitable for a range of applications.

4. Weldability: 1035 steel has good weldability and can be easily joined by welding methods such as arc welding and gas welding.

5. Machinability: 1035 steel has good machinability and can be easily machined using conventional techniques.

6. Corrosion resistance: 1035 steel has limited corrosion resistance and is susceptible to rust and corrosion in certain environments.

7. Cost: 1035 steel is relatively inexpensive compared to other steel alloys, making it an economical choice for many applications.

Note: The properties of 1035 steel can vary based on the specific conditions of the manufacturing process and the heat treatment applied.